Subframes

The Planner and the Kid went to big city #1 for a week to build subframes needed to support the Shop boxes. According to regulations, the floor of the shop must be 18″ above base flood elevation of 7 feet which results in a finished floor height of 4 feet above natural grade.

Before any frames could be built, materials were needed. This above all other steps in the subframe building process was the most infuriating and time-consuming. Apparently, it was lunch time before they even got to the final designation to build the subframes. Yikes.

Oh well, once there, the work went smoothly and fairly quickly. What was to have taken all week resulted in only three days worth of work and the boys were back home by Thursday at lunch. I would say that was a fair turnaround time considering three hours to get there, two hours wait time for materials, and three hours return trip. Not bad at all. Wish all trips went this well. Of course, some of the reasons the trip went well was once again the use of the full furnished shop with forklifts, cutting machinery, and help. The other reason was the Planner being the Planner had all the dimensions for the subframe prepared ahead of time. This meant once materials were sorted and arranged, cuttings were quickly started.

One of the best tools available for use is this bandsaw. It can be used to cut materials in many different shapes and sizes and can cut on many different angles. Cutting perfect 45-degree angles is just a matter of setting up the saw. Yes, setting the bandsaw up can take some time. And for some people, learning can seem overwhelming. But I can attest, it seems more difficult than it is. Having used the saw myself, once it is done, the jitters experienced seem silly. With that being said, all I had to do was cut a straight line. Well, it doesn’t matter because I did it myself!

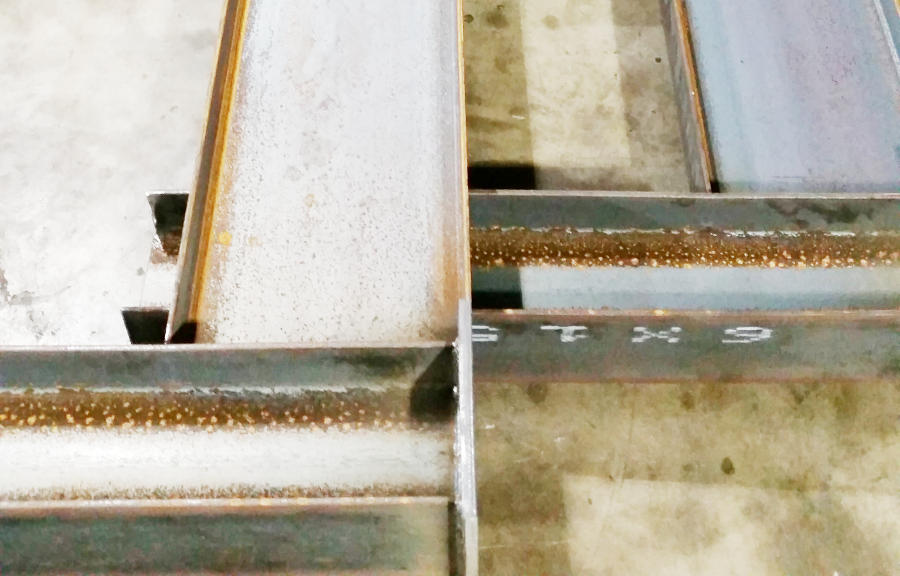

With pieces all cut, assembly was next. With the use of industrial grade saw horses and numerous C-clamps, the subframes were ready for tacking. No, not welding. Tacking. Tacking the subframe together helps to ensure the material does not rack or wrap. And this is exactly what would happen if one just started welding the frame from one end to the other. By the time the welding reached the far end, the subframe would look like a puzzle piece.

Even once tacked, the subframe should be double and triple checked for level. These steps are repeated again and again after every new section of the frame was added. It is time-consuming? Absolutely. Is is necessary? Absolutely. No questions asked. Just having the subframe warp an inch will result in the shipping containers not sitting flush. It would be like sitting at the wonky table at restaurants. You know the ones I am referring to. The ones where a stack of sugar packets or napkins have been shoved under a leg in order to keep your tea from sloshing over. Yes, having the subframe warp would be just like sitting at that wonky table.

But with this, it would be more like the table that has packets of sugar or napkins under two legs in attempts to keep it from rocking left to right and from rocking back and forth all at the same time. It is a table, not a balance ball. I am trying to eat, not work on core muscles. Being I am at a restaurant would also mean I probably do not work on my core muscles to begin with. No, wait, no probably needed. I do NOT work on my core muscles. There I said it.

Another reason, the job went so quickly was the amount of time dedicated in those few short hours. If you look closely at the far right side of the picture where the level is, you can see the darkness through the opening of the shop doors. Why you ask was the Planner working at 10:30 at night? There is no TV, no internet, no wife, no comfortable bed. Therefore, there is just work. The sooner the job gets done, the sooner the Planner and the Kid can come home.

And that is exactly what they did after the four subframes and cross pieces were completed. The trailer was loaded up, lunch was grabbed at the favorite Mexican food restaurant, and home they came.

Two things were observed upon their arrival. One, the steel which was once a pile when purchased was assembled very OCD characteristics. Haha, it is rubbing off. And two, the steel was a beautiful blue color. One must appreciate raw metal when it can be observed and while it lasts. My guess, living here in the salt capital of the world, this steel will be rust colored by the end of next week. Winter mornings are always wet with dew and fog. With moisture comes salt corrosion. With corrosion comes the fact that assembly of these subframes and painting needs to happen post haste. In fact, it should happen tomorrow. It won’t, but it should. And do you know why it won’t? Because tomorrow we are going back to big city #1 and it has nothing to do with the advancement of Boxes in Fields. Hopefully, erection of subframe will continue next week.