Rain Water Collection System Update #2

Don’t know about you, but here at Boxes in Fields we hate time change. Dark is for sleeping. Not wanting to be cramped inside the too small Rainstream and wishing to ward off scenes of “redrum” playing in our heads, the Planner decided to be productive at 6:12pm Saturday evening. Seriously? Having still not completed the RWCS and needing to move forward with the final stage, the Work Box desk had to be removed.

Why, does the Work Box desk need to be removed? Well… the Planner, he is human after all, makes mistakes. Lacking forward vision, I am little help to him when it comes to visual concepts. During the time the desk was made, RWCS was not on our forethought meaning we did not leave room for the PVC piping to run from ceiling to floor.

As an added bonus, removing the desk allowed for a couple of touch ups on the green paint. Having only one can of spray paint during the original build, the coverage was minimal. So with another can bought, the desk was roughed with sandpaper and a new layer applied.

Some areas were worse than others, like the section directly in front of my computer. The paint has been gone so long the rust is working its magic. And in the words of Sweet Brown, “ain’t nobody got time for that”. Do you remember Sweet Brown and her fire? To this day, the Kid from out of nowhere with perfect timing and accent will bust out with her famous line and have us giggling. It’s classic stuff. Classic. Anyhoo..

Back to work. Having removed the desk, the Planner measured the distance from the wall to drill a 2″ hole for the PVC piping. It is important to make sure the hole is far enough away from the corner pocket and the frame work to allow for room under the box. More importantly, the PVC must run as close to the corner as possible to allow for more room on the desk.

With the hole drilled (sorry no pictures), the hard work began. Removal of the PVC caps. The south wall was hard and there were not any obstructions. The North wall as you can see has a cabinet in the way. Being welded to the wall for safe keeping during the next hurricane (hopefully not anytime soon), the cabinet could not be removed without a lot of work. As besides, it not really in the way so much as it makes the removal of the cap more of a challenge. If challenges are good for the brain then the Planner should be super smart for the time spent in cap removal.

Immediately upon slitting the PVC with the disk grinder, water starting dripping onto the floor. No wait, not the floor, straight into the hole in the floor. Way to go Planner in locating center for pipe hole.

See, no water! Being dark and all, the Planner was not able to tell if the frame work was cleared with enough spacing and we had to wait till Sunday for verification.

Having measured the distance from the ceiling to the floor, the Kid wanted to handle the “big guns”. His words, not mine. Just look at his concentration on his face. One would think this was laborious work.

Leaving the angles for the Planner to measure, the insert was ready for brain cell killing PVC glue. Not once since all those years back when I first used the blue and purple glue to install electrical lines have I ever jumped for joy at the potential need for usage. This stuff is bad. As in bad, bad. Left in a small room with one open jar, the occupants would become zombies. I have deemed the PVC glue liquid lobotomy. It is so bad that just one drop removed this two part epoxy paint without any sticky residue remaining. The glue completely ate the paint. Nasty stuff. What is worse, I can never use it without making a mess. Not wanting further paint damage to the Work Box, the remaining PVC glue was done over cardboard. Good thing too, as a major mess was made. Ugh.

Working late in the night on Saturday, Sunday dawned bright and late. After leaving the comfort and warmth of my bed and making breakfast, it was just after 11am before work was finally started. Hey, it is Sunday and Saturday and Sundays are stay in bed days. See the correlation there, S is for Saturday, S is for Sunday, S is for Stay in bed. Makes sense to me.

Needing time for the desk to dry, modifications came first for the days agenda. The corners were measured and marked, leaving just the bare amount of gap. Never say the Planner over measures anything. Why use 1.5″ inches of 1.45 inches will work? Waste not want not and all that.

Cutting the corners out turned out to be more challenging than thought. Not halfway through the first cut on the first corner and the desk frame shifted binding the portable saw. After much work and frustration, the saw was freed and the Planner was left to rethink how to cut second corner.

Thinking in progress, the Planner cut the second half of the first corner and tweak went the desk frame. Well damn, this project just gets better and better. Now the Planner had to decide how to keep the frame square while at the same time keep it from binding at the blade. He tried using a piece of angle to apply pressure to keep the frame flat but as you can barely see the right side is still higher than the left.

Leaving the Planner to his thoughts, I manned the band saw and cut out four corner plates.

Once cut, they were corners were rounded for safety. Don’t they look fantastic? I had wanted to take a picture of all four but the Planner was faster at his job than I expected and before I knew it they were fully welded into place.

Not bad for a repair job if I do say so myself. It even looks like they were made to have the corners removed. Now for a quick grind job to remove tag ends, burrs, and whatnot and then touch up spray paint.

Leaving the desk to dry, the two PVC pipes were installed and glued into place. They tucked nicely into the corners and fit snugly into the perfectly centered holes in the floor.

And guess what, the desk fit perfectly into place.

In case you are wondering, the Planner did leave enough room for the PVC, but just barely. Guess this game of Just Right/Too Tight is something he does to challenge himself, as he constantly does it. Not me, I would have removed another 1/2″ and been safe. It is not like the back corner of the desk is used for anything anyways.

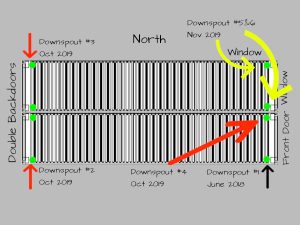

Before Sunday’s work could end and play begin, the Planner had to make sure his idea for linking the four downspouts was going to work. A couple of bends and a couple of unions and his idea will work as planned. Of course it will. Never doubted it.

Monday afternoon, the Kid and the Planner continued on the RWCS. The Planner is dead set on completing this project. The Planner installed and connected the PVC bends and piping together.

The Kid rolled the water tank over and then pushed and shoved it into location. See Kid, being short (and limber) does have its advantages to being tall and stiffly old.

By days end, the Planner had all but the last section installed as he did not have enough materials. A temporary pipe was installed to allow for water to drain into the 55 gallon drum. Bummer, all this hard work and the new water collection tank still could not be used.

Oh well, another productive weekend and another step closer. Six downspouts installed, two to go. Wait. That’s not true, either. There is the whole underside connections, too.