Concrete Rebar Mat

And so we wait for rain…

And rain it did. Water standing deep enough the waterproof boots were water logged. Trying to keep on schedule despite the weather, the Planner continued with concrete pad preparations. There were end bed plates to make and water lines to lay in the ditch between the two boxes. The plastic wrap did keep the water from soaking into the form boards but it did not hold up to the endless wind and had to be restapled several times. Mud at the bottom of the ditches was still an issue so to staple the plastic for the third time the Planner went barefoot. Spa day anyone?

Finally at the end of January construction resumed on the pad. Three dump truck loads of sand were delivered and spread over the ditches to create a nice smooth work surface. Not giving clear delivery instructions by the concrete foreman, the first load was delivered directly over the spray field. Luck was on our side as the driver missed the spray head with the truck tires but not the sand itself. Luck was also on our side as we were home and could direct the remaining two truck.

When the concrete sand spreader guy came he had to be guided as to not run over the spray head. As we are not entirely sure where in the sand pile the spray head was this was a tricky process. Luck was still on our side as the sand spreader was the owner himself. He wanted to make sure if the septic was damaged it was done by him and not his crew. He was also an expert at this skid steer and could run the bucket along the pokey grass collecting sand and never did snag the spray head. Just over an hour after he arrived three dump truck loads of sand was spread and he was gone to the next job. Or gone for the day as it was Friday.

February came and went in a bang. By end of day that first Wednesday, the Planner had dug the ditch for the water line ensuring it was to the correct depth with assistance from El Gato. A two inch PVC line will run from the Shop Box to the Work Box and beyond for the rain water collection system on the Shop Box side.

In order to connect the water lines that were already under the Work Box a hole had to be cut into the form board. Why do once what can be done twice. Just kidding, one PVC is for rain collection, one PVC is for the house.

Sunday to rest of the world is a day of rest. Unless you in the construction trade and have to work around the weather. With more bad weather coming (yeah winter again) and having a dry work pad, the construction crew arrived first thing Sunday morning like it was any other work day.

There were lunch boxes, music boxes, and supply boxes. There was concrete chairs, rebar anchors, and of course the Planners end bed plates. Concrete chairs to keep rebar off the mat, the anchors to tie the rebar together and end bed plates to tie the join the strength from the rebar in the pad to the strength in the columns being used to support the roof/House Boxes 14′ feet in the air.

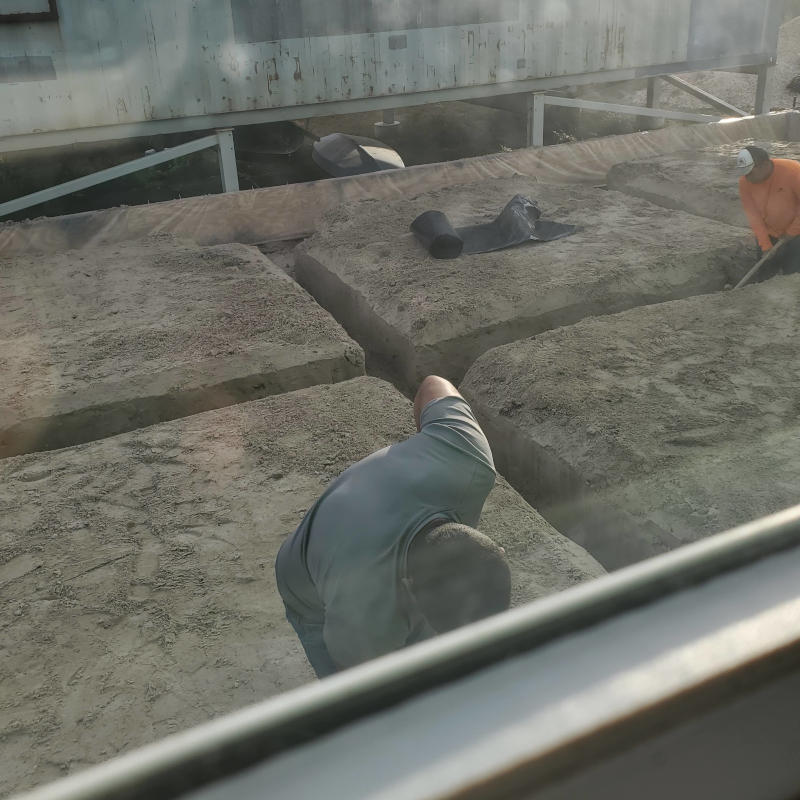

These guys worked from daylight to dark digging ditches and prepping for rebar mesh work. Heavy plastic was laid and rebar sticks were tossed on top to keep it from blowing away.

Monday and Tuesday passed with no further activity on the pad but Wednesday the entire work crew must have been delegated to this job as there were no less than ten men working to build rebar cages, lay rebar mats, and to tie and anchor rebar.

These men were trying their hardest to beat the weather that was coming. Sadly, the did not. After another half day of work today in almost freezing temperature the men called it quits just a few hours after arrival. There is rain schedule for tomorrow anyway and the concrete truck cannot pour in the rain. All that is left are a few dozen more chairs in low spots, a couple of missed anchors, and one readjustment of a rebar cage that is too close to the form board.

Looks like Boxes in Fields could have a concrete pad for Valentines Day. Nothing says I love you like a 30×40 slab!