Beam Me Up Outside

After a productive weekend, Monday was used as a down day. The conex box was cleaned up from its weekend worth of work and then just observed for its general awesomeness. With nothing else on the agenda, the Planner and the Kid decided to make a hot shot run to the Big City #1 to pick up materials on Tuesday.

Of course as with all things at the metal store, getting there is the easy part. Picking up the materials, which were pre-ordered to ease the process, is like watching maple syrup run in the dead of winter. Slow, slow, slow. These workers are not union but they could be. Having hours to kill, the Planner started daydreaming. Oh lord, here we go again. Daydreams lead to hours and hours of lost time. Time spent on ideas that may or may not come to fruition. The problem with dreams is they are usually better as dreams, not reality. It is a dream. Yes, you could fly to the moon, but there is a process to get there about 40 thousand steps long. It is not just as simple as putting your hands in front of you and pushing off with your feet. Who do you think you are Clark Kent? Get real.

Ah, the waiting place. While there waiting in line, he started daydreaming about installing an overhead hoist. Don’t get me wrong, an overhead hoist is awesome. Especially one of this caliber. They are great for moving heavy objects to and fro. Just grab the chains, lift and go. For example, too lazy to walk? Problem solved: make chain loops, insert feet, and hold onto chains as hoist moves down the work area. Yeah, I could totally see having a hoist of this size. The problem with his dream is that the conex box is only 9 feet tall. This does not leave enough head space for a hoist. Sometimes the Planner forgets he is 6’5″ without shoes. Yup, keep dreaming…..

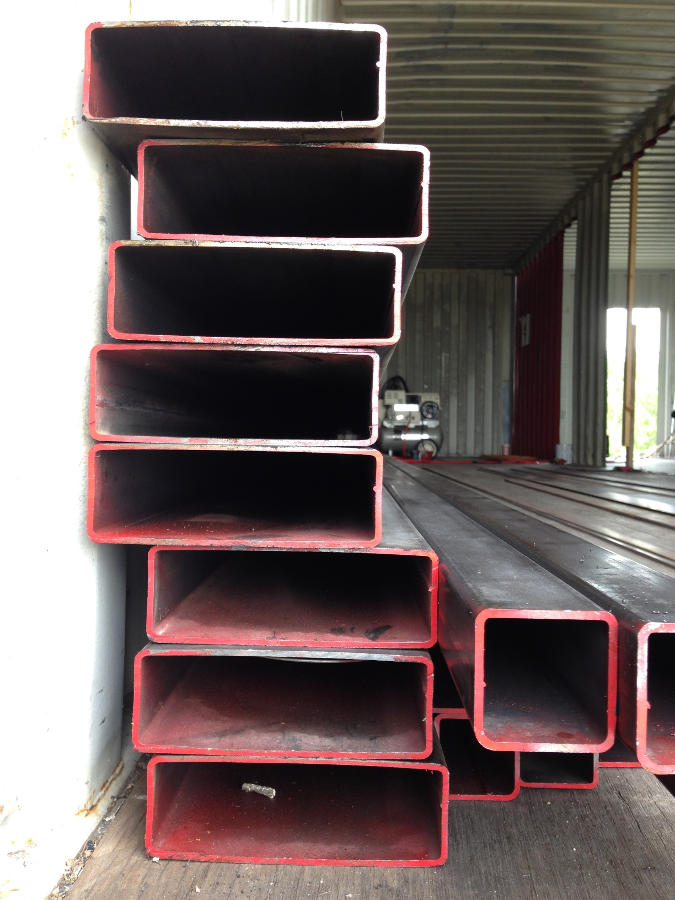

Materials were finally loaded, the boys spent the night with the Doubter, and immediately got to work when they returned home on Wednesday morning. Materials cannot sit outside here in the land of salt air. What is a rusty spot today will be a rusty pile tomorrow.

Materials were unloaded into the shop. Hot dog! The shop. Guess I can start referring to the conex boxes as the Shop Box now. Yea, that makes us sound pro-fess-i-nal. I can hear it now. A friend drops by and asks “Where is the Planner?” “Oh” I say, “he is working in the Shop Box.” Yup, totally gonna call it the Shop Box from this moment forward.

With the materials unloaded, the trailer was parked at the other end of the property to be out of the way. The Planner being super chill and happy with the progress decided time could be spared to let the Kid drive back to the shop. Hehe, told you I was gonna call it the shop at every chance. The Planner put the truck in four low, the transmission in low, and away they went. Put-put-put.

One small drive for you and me, one nerve wracking experience for the Kid. I was told he freaked because as he drove a snail passed them by. Go figure, the Kid can drive the tractor like a seasoned farmer. Put him in a truck and he wigs. What a goof!

Wednesday morning the Planner decided enough down time has passed and cuttings for the beam for fitting and welding began. The wide flange beam purchased is a W14x22. This purchase was of great debate. The engineer in the Planner screamed and screamed the next size smaller wide flange beam W12x19 was adequate. The numbers were located, the figures were calculated, and the results were reported. Yes, a W12x19 beam would meet all the structural requirements. Yes, the next size beam up (the one purchased) would meet the requirements as well but was not needed. Yes, the next size beam costs more, weighs more, and takes more work. So why was the larger beam purchased?

Deflection. Pure and simple. The larger wide flange beam W14x22 resulted in a lower deflection in the roof. Less deflection means less sag in the roof. In layman terms, a stiff roof is a better roof. Just look how much this beam sways under its own weight in the normal everyday winds. Now image what a smaller beam would do to the roof with 150 mph hurricane winds.

Or was aesthetics. He did keep mumbling a larger beam would look better from a distance on top of the Shop Box. Wow, I didn’t know the Planner took architecture classes in college. Pretty sure while working at the engineering firm after college his biggest complaint was about the crazy notions from the architects they worked with. Yet here he is 10 years later doing the same thing. Just goes to show you, never say never.

“Beams ready for placement, hurry home” came the text on my phone Thursday at work. Like I diddle daddle around at work. Puh-lease. I try my hardest to leave 4pm every day. It is not my fault I get stuck there, honestly. Time just slips away. Anywhoooo. Just to be sassy, I left at 3:45 to hurry home. That will show him.

I get home, with tasty diet drink for me and an Excelsior of Life for him, to a tractor attempting to pick up a beam onto the shop. Jesh, I get home early and it goes unnoticed. That’s what I get for being sassy. Hate it when the Planner gets focus. He is no fun. No fun at all.

The W14x22 wide flange beam weighs approximately 880 lbs. The Shop Box beam weighs 860 lbs. Since I don’t have any weight measuring tools to to weigh the discarded, I am assuming the beam’s weight. Now is not the time to get technical on me. It is not relevant to the story. As I was saying, the beam weighs 860lbs and the tractor can pick up 2000 lbs off the ground. Picking up and lifting up as it turns out are two different things. The tractor could pick up the beam but could not place it onto of the shop.

Apparently before I could even get home, the Planner had already tried to lift the beam onto the box with the standard tractor forks. Fork extensions were added and the tractor could still not place it there. Want proof of the weight? Look at the squeeshed (that is squashed combined with squeeze) front tires. Nope, not gonna happen. Good thing the Planner is the Planner. Backup plans were already in place. Tomorrow the Doubter is coming down for the weekend for the weekend again and this time he is bringing a forklift. Sometimes having friends in all the right places makes work so much easier.

In my next life, I am gonna be like the Planner when it comes to plans gone wonky. He is always calm, like water off a duck’s back. Oh well, tractor can’t life beam, what’s next then. I am more of an A-B-C-D kinda girl. The Planner is more an A-B-9-$-M-2 kinda guy. Yet, somehow we mesh. Hmm, interesting.

Having to go to work sometimes is no fun. I love my job but I miss all the good stuff at home. While I was at work on Friday, the Planner, the Doubter, and the Kid lifted the beam onto the roof of the Shop Box and started the arduous process of welding it into place. Boy howdy, did you read that fancy $10 word in that last sentence. Bet you didn’t think my vocabulary ran that expensive. It does and higher, too. I’m a classy kinda girl with a whole cornucopia of vocabulary words.

Have to say, the beam looks impressive even from the pictures. I have not seen it personally because, well, umm, you know…. ladders really aren’t my thing.

Not wanting to work too hard and deciding to enjoy the nice evening, everyone cut out of work early (except me) and chilled around the house. Dinner and family, nice. All things were going smoothly until the rooster decided he needed a new perch to crow from. Guess the tree limb outside the trailer window was not good enough. Now he needs to stand on the back cover and crow straight into the window.

When he was shooed off with my broom, he ran to the underside of the Doubter’s trailer and wedged himself into a cubby. Just great. I’m yelling at the stupid chicken causing the dog to lose her mind, the Doubter and the Planner are laughing at me from the picnic table, and the Kid is running around chasing the dog chasing the chicken. From the outsiders perspective, I am sure we looked like a three ring circus. Stupid rooster. You want him? He is free. F.R.E.E.

Saturday morning dawn calm and clear and both men got to work bright and early. There were things to get done the Doubter said and he didn’t come here to sleep. But the weekends are the only days I can sleep late. Being the Doubter is up at dark thirty every morning, he thinks 6:30am is late. Can’t argue with those who offer free assistance. I can always sleep when I am dead, right?

Okay then, let’s get this party started with the door frame. The conex wall was ground smooth of any cutting debris on both the outside and inside. This would allow the frame to attach easier. Wake up neighbors, it is time to start your day, too!

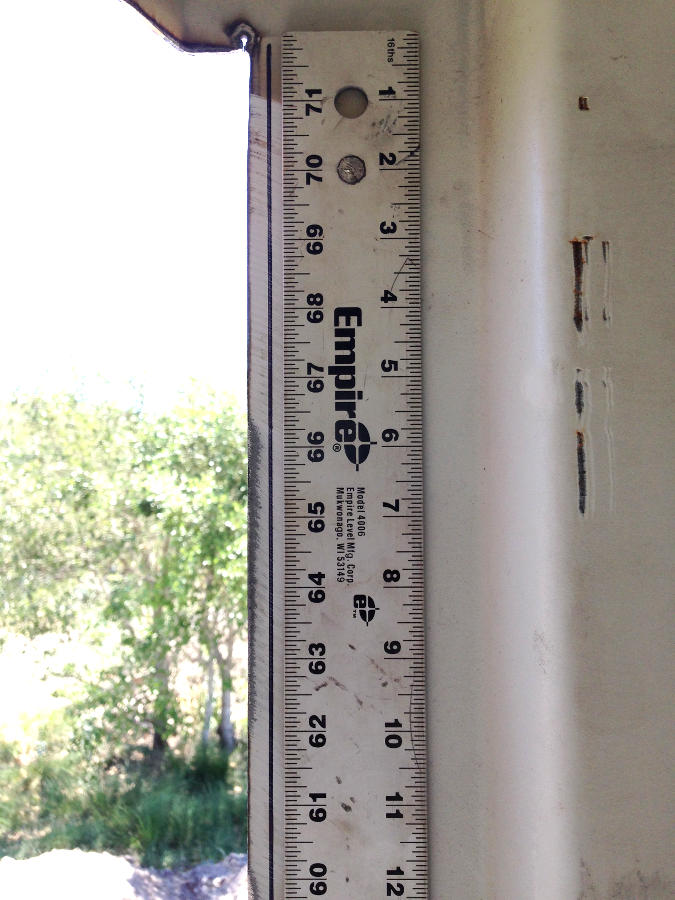

Measurements were taken, 2×6 channels were cut, and the frames didn’t fit. It was guessed, the guide used when cutting with the plasma cutting did not hold true and the door opening was out of square.

After much debate on the easiest way to rectify the situation, it was decided to attach a frame to one side and then square the door opening from there. The left side frame was attached and tacked into place. A new straight line was drawn down the right side of the door. The plasma cutter was drug back out and the door opening was then squared. Weeeeeellll…. as square as square was gonna get in this case.

Materials were cut, installed, and tacked into place with great efficiency.

The Planner would cut, the Doubter would install, and the Kid ran back and forth for water and Gatorade refills. Busy little beavers they were. Cut, grind, hammer, torch. Rinse and repeat.

Due to space constrictions, the use of a ladder was needed to install, plum and level, and tack the beam from the outside. I felt bad for the poor soul on the ladder and their poor soles. Work boots designed to stand on concrete all day are NOT designed for ladder work.

Last on the day’s agenda was the bottom frame of the door. This should have been the easiest part. It did not require the use of ladder nor was it done overhead. Everything was at the tip of your fingers. But as with the entire door frame, it was not. The bottom frame turned out to be more work than the rest put together. For whatever reason, the channel either was too high or too low on the outside. There were many on-the-fly decisions made about how to level the bottom frame. Some shims were added underneath and the channel was secured into place with a few choice placed tacks. Still needing to be fully welded into place but lacking energy, the boys called it a day.

It is the weekend by the way. Some people would like a break from work. Dinner was served and the company was enjoying the evening when the three ring circus came to town. Again. Last night I was nice with a gentle broom. Tonight, it was the garden hose. Ha! That will show you stupid chicken. As in all things in life, the stupid chicken had the last word. He did leave the back of the trailer for a while to crow elsewhere only to decide the propane tanks made great roosting posts. Cock-a-doodle-doo the rooster is crowing. Ugh.

Sunday was spent just welding and welding and welding some more. The door frame was fully welded on the inside and on the outside. Weld, break. Weld, break. It was a hot, hot day for the Planner.

Monday and Tuesday the Planner cleaned up the Shop Box from the weekend’s worth of work. Grinding dust, cutting dust, welding dust, and dirt dust galore. Yes, dirt dust. I was on a roll with the dusts. Just go with it. Then with a clean Shop Box, he painted the door frame, installed a second hand purple door, and prepared for Wednesday’s work.

Wednesday, the Planner welded one side of the beam (all 40′ in case you forgot) and then checked for leaks with water. Any leaks were ground out and re-welded. Fortunately, there were only two leaks.

Thursday, was one and the same as Wednesday. Grinding, welding, testing 40′ of beam takes longer than one wishes. Luckily for the Planner, there was cloud cover and gentle breezes both days. Had there been glaring hot summer sunny days, this two job would have been closer to four.

Since we enjoyed Thursday so much, we decided to spend Friday and Saturday doing the same thing. We visited some friends, ate some tasty Whataburger, and did some general around the house clean up. Gave the chicken some sand to do their thing. Be it they scratch or eat or just rub their beaks, they were happy birds. Not the rooster, he is not allowed to have fun. What a busy two weeks at Boxes in Fields.