Concrete Forming

Let the forming for concrete begin. Ditch digging was easy work compared to the work that lies ahead of Boxes in Fields. Concrete workers we are not but money tight we are. Needing to save as much as possible in labor costs the Planner was approved to build and install the concrete forms. Of course, being the planner the Planner is, they were built to code for strength, durability, and reusability.

Saturday after Xmas, as soon as the hardware box store opened Boxes in fields was standing at the door with carts at the ready. There was a truck bed of 2x4s along with saw blades and gigantic buckets of screws to purchase. Laminated plywood and metal spikes were purchased a few weeks back as they had to be special ordered.

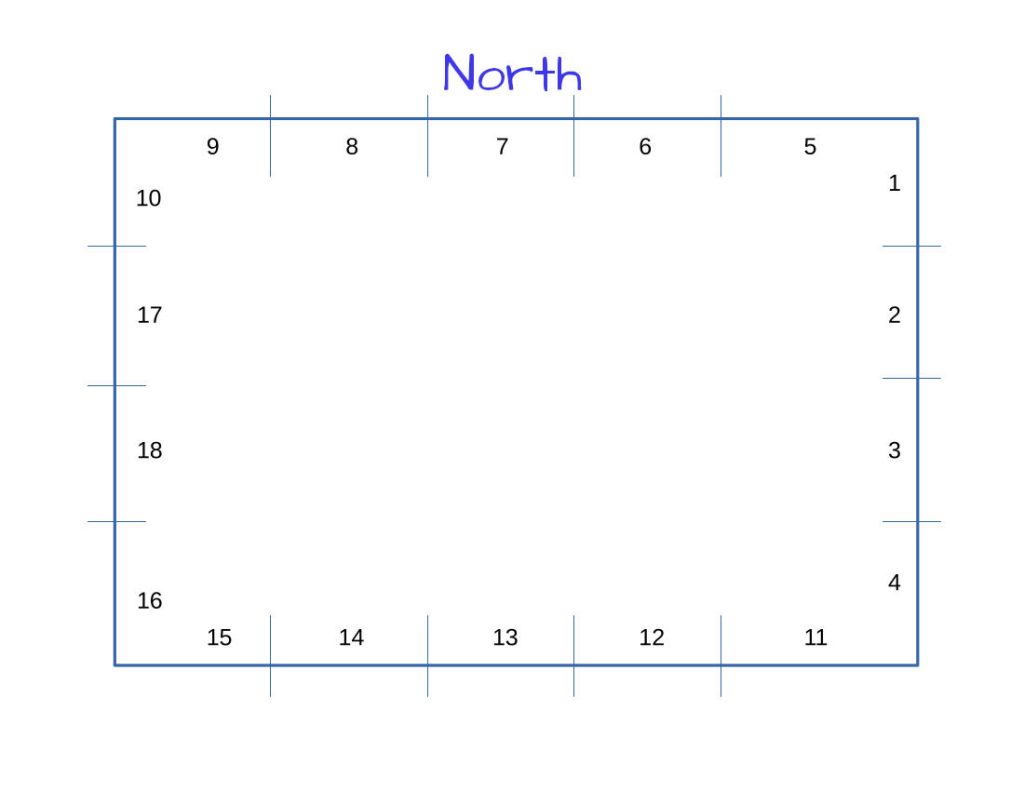

It took a few tweaks but the first form was set in place late afternoon on Saturday. Again, not knowing what we were doing there was lots of referencing to the internet and books before the Planner was happy.

Holding the flat face against the pink string line is harder than it looks. The form board were built with four inch tags that set into the ditch but as the ditches were not smooth this assistance did little to really assist. Flat metal stakes were used to keep the form at the correct height elevation and kick legs were used to kept the form the correct spacing against the pink line and secured into wooden anchors two feet deep into the dirt.

What better way to ensure the form board are securely set into place than to jump up and down on them. If the boards can withstand close to four hundred pounds of weight pinpointed at four feet (literally four feet, two for the Planner, two for me) then the whole unit should withstand concrete being poured and tamped into place.

Sunday started off on the wrong form. Wanting to smooth the dirt work at the bottom of the ditch the Planner took to gently removing tiny bits with a flat edge shovel. One thing lead to another and the dirt wall collapsed creating a giant hole where the form should have rested. Upon fixing dirt around form #1, dirt work for the rest of the forms was smoothed out before further forms were built and installed.

Monday forms #2/4 were installed completing the east wall of the concrete form work. All boards were secured into place with metal stakes for height and kick legs for in and out placement.

Monday afternoon form boards #5/6 were placed along the north wall. Even with all the presmoothing of dirt, once the boards were place more dirt was removed from both the front and the back.

Tuesday more kick legs were needed. To the scarp wood pile we went in search of leftover 2x4s from the concrete piers used to secure the shep tubing into place while concrete was poured. First used on Footing #1 on the Shop Box way back January 2017, then again on the footings for the Work Box year later in January 2018, and now they’ve been repurposed for kick legs for the concrete pad. Think we have gotten our moneys worth on these 2x4s. Upon wrecking, form #7-#10 were installed.

Wednesday we had a late start resulting in only #’s 11-13 on the south wall being installed. More than half way done with form boards, the three of us had finally a grove that worked well. It also helped the dirt on this side on the pad was easier to smooth out with only one blow out under the backside occurring.

Speaking of the backside, the backside of the form boards are just as impressive as the front. The front is smooth to touch and if you stare at it one can get lost in the swirls on the board. When looking at the backside the angels and lines make for a wonderful abstract view.

Thursday was New Years Eve and Boxes in Fields celebrated with yet another lake. Drat, all our hard work out the damn window. Now the smooth finish is going to warp and bulge and twist. Only time will tell just how bad the damage will be. Only time…