Rain Water Collection System Update #3

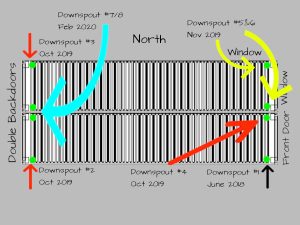

Ah, the never ending task of completing the RWCS. Back in November, Boxes in Fields had half of the Work Box plumbed for water collection but the project was never completed as materials were lacking. Between then and now, time seems to have slipped away quite quickly with work and other repairs. With the rainy season upon us and the water tanks almost empty, it is time to finish the collection.

Last week started the final stage with the removal of the last two PVC caps. And true to firm the last two were just as difficult as the first six. Not even wasting time with wrenches and straps, the Planner went straight to the cutter. A quick zip here, a quick zip there, and a twist with a extra large screw driver and off came the caps.

Unlike previous inside corner downspouts, the back wall inside corners were combined into one to save space in the working/loading area. It would be our luck that the last of the pass thru cutouts in the floor would give the most grief. The drill was dull, the wood seemed extra hard, and the holes didn’t align on the underside.

Yes, you read correctly. The holed didn’t align. Again. It is really is difficult to align a hole from the topside to underside going ons. See the dark line across top of the hole cutout? That is the frame channel under the box. Since there is no backing up, this misalignment would just have to rectified on the underside. In the famous words of Scarlet O’Hara “Why do today what can be put off until tomorrow”. Okay, that is not exactly what she said but that is what she should have said. It’s funnier.

Downspout number two and three were combined to save space and eliminate the corner PVC issues. Having a need to have full access to the open doors is a must for the Work Box. There are pallets moved in and out weekly and at times the pallets are two wide meaning there is not an inch of room to spare when loading pallets into the box with the tractor. With outside corner PVC pipes already gobbling up about 6″ from the wall, combining and placing in front of the two adjoined boxes seemed the most logical.

To ensure the safety of the PVC downspout a metal safety cage was installed and welded into place. And, yes it too will follow Scarlet’s words and be painted tomorrow. Well, not tomorrow tomorrow. But a tomorrow.

Having all the downspouts complete inside the box and having already started on the water collection storage tanks under the box, today was the day to connect the boxes to the tanks.

Maybe it was not today, or maybe it was yesterday. Days just run together around here.

To ensure an even flow of water collection, the tank ground was leveled out with a 2×6. Filling in any holes as it was scrapped back and forth across the pad, the fresh fill was then stepped on with three sets of feet to press down and secure a solid base.

The front tank not only had to level with the world, it then had to be leveled to the tank the back of the box, too. If one tank was higher than the other, water would not even out between the two resulting in one tank always having more water than the other affecting the pumping system.

Not wanting to restrict any water flow, two inch PVC pipes were used the whole way through the water collection system. The inlet into tank; however; was only an 1-5/8” in diameter. Opening the inlet to fit the two inch pipe made a huge mess. Tiny little shards of PVC went everywhere with no ideas as to how the PVC ribbons will be collected from inside the tank itself.

A test pipe was fitted and almost dropped into the tank. Push, push, twist, twist and stop! The sample was left in place and taped closed to ward off any four legged critters that might decide living in a tank would be a perfect home.

With a better understanding of the water line layout, the water pump stand was quickly built, welded into place and then primed. The pump being used will not be the final pump as it is too small for a completes RWCS. But with only two boxes worth of water to collect right now, the recycled pump from way back at the Water Management System days when we were collecting RO water castoff water.

Don’t you wish you could squat for hours on end painting like the Kid still can?

A connecting ditch twelve inches deep was dug from the back tank to the front tank.

The south wall downspout was connected to the north wall and a t-union was installed for clean out purposes, future water inlet from the main house, etc… Installing the four way pipe and ensure left and right was level while maintaining proper drop into the tank itself was a little frustrating. There was a lot to manage in a tiny space.

From the pump a check valve was installed to keep the pump constantly primed.

Sometime during the week, the water pump platform was painted and an electric line installed. With the pump primed, the tanks were back filled from the 3000 gallon storage tanks to max capacity and the whole system was tested. Fully priming the pump took a few attempts but once the air bubbles were worked out, the pump flowed, the water float valves inside the tanks were adjusted to keep just a few inches of water at the bottom, and done. The Work Shop Box water collection system is up and running. Now for the rain….