Windows to the World

Ever since COVID, construction materials have been difficult to come by. Some more so than others like PVC, framing lumber, and windows. Knowing and planning accordingly are two different things. I knew it would take longer to order windows from a quality window supplier versus off the shelf windows at the local hardware store. Having nothing but water leakage issues on the windows in the Work Box, I decided having to wait for better quality windows was worth the delay. Ordering the windows and and then being told the actual time line for delivery was staggering.

If I had known it was going to take so long for windows to be delivered, I would have ordered them before the window openings were cut from the panels and the frames were built. Windows would have been ordered before summer since I already knew what sizes the windows were to be for each room. Wait! They were ordered before summer. In fact, they were ordered way back in April before the garden was even removed, the footings placed, or the boxes moved and joined.

Windows took six months to arrive and then when they did finally were delivered there were manufacturing blemishes that had to be rectified. As new construction windows, the edges should have been smooth or even rounded not left jagged and broken. Not wanting to wait for them to be fixed, a deal was hashed out with the supplier leaving the Planner to carefully grind off the edges on each window. Six windows, four edges each. Luckily the flapper disc made the work a breeze. Burnt plastic stinks, by the way.

With windows ready, the window frames were prepared. In order for each window to fit even after the edges were altered, the framework required the corner welds ground smooth before the window would fit with some wiggle room. Having a window too tight in the framework is a no go. There needs to be room to install the correct amount of caulk. Each corner was painted with a cheap bristle brush that left the once smooth texture rough and ugly. Guess it is a good thing the window and its casing will cover the majority of the framework.

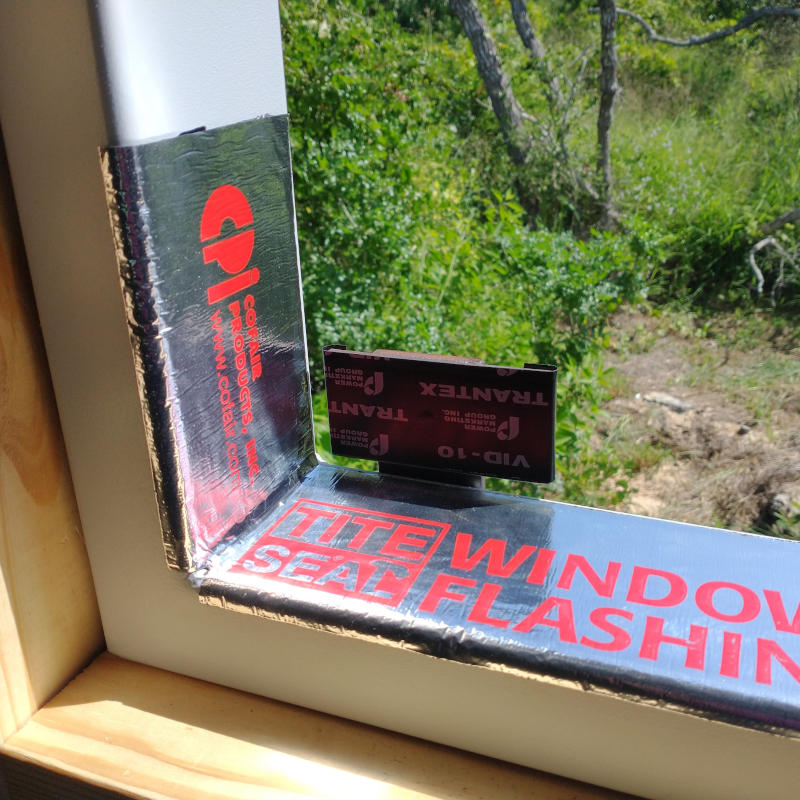

Some of the issues with the windows in the Work Box come from water leaking around the caulk and sitting on the window frame causing the frame to rot out in the corners. All new windows are to be installed over a flashing that directs the water outward but metal framed windows lack this ability. To compensate, the Planner found this tar lined aluminum window flashing at the local hardware store. Once the backing was pealed and placed onto the window, there was no removing it with a GIAGANTIC MESS. This was a two person sometimes three person job. Lucky for me the Doubter came down this morning to help for a few days. Heck yeah, let the work begin.

Needing a way to keep the windows from falling outside when installed, the Planner came up with these home built stopper tabs using the preexisting holes for the plywood covers. This allowed the windows to be moved left and right to center within the frame and install plastic shims to keep them spaced correctly without any worry of them fall out through the window. This was a major problem when installing the windows in the Work Box.

To keep the windows protected the metal shim was covered with PVC tape. Very thick and very smooth. Since each window had its own set of tabs, this allowed the Planner time to caulk during down times.

The Planner despises caulk. He has tried all brands, all varieties, all weather, and they all leak. This go around, he is trying the weather max. What we need is rust proof caulk that allows for temps to reach 100+ degrees and will tolerate wind vibration.

With tabs on all four corners and the windows shimmed correctly, each window was tested to make sure they opened and closed correctly. Open. Close. Open. Close. And as I was viewing the on goings outside the bedroom window but what did I see? The two loudest, nosiest chickens!

Chicken (the rooster) who loves to crow his stupid head off under the window and Squawky McSquawkerson, our longest living resident hen who is molting. Luckily for me, my Windows to the World, while not installed with screens just yet, are closable and can drown out their noise. Poor Squawky, having been a resident since Feb 2017, I can honestly say she has never molted to the point of bare skin. Doesn’t she look just miserable?

Some of the other hens are molting as well as can be seen by the number of feathers that have piled up along the coop wire but none as much as Squawky. Sadly for her the molting will take way longer than the installation of these windows. With the Doubter help, all six windows were installed in less than one working day. I just love when the Doubter comes to help because between the two men, work gets done because neither one needs to tell the other how to do things as they speak the same language. The Doubter is not hesitant on tools or installation. Yeah for the Doubter and the Planner and their ability to work seamlessly together.