Blasted Sand and Wind

Wow, I am thirty something and yet I am still amazed at how quickly time flies. It has already been four months since moving to Boxes in Fields from the RV park. The Kid is going to be the big one-zero in just nine months. Nine months. Holy crap Batman, kick in the afterburners and get moving on living. Time is ticking away.

But as life has it known over and over, one can neither wish to have time move faster or slower. It just moves. Things like weather and tools and modifications just take time. It has been more than two weeks since the subframes were erected. In that short amount of time, a strong layer of rust has built upon the frame and new welds. What once were shiny silver welds are now yellow, brown, and red in rust. Yuck. Tick Tock goes the clock.

With 8″ of rain here and gone, there were other reasons for delays such as chicken runs, the Doubter moving his trailer down, and the ordering of parts and tools. Numerous parts and tools. Amazon is a great in catering to us Americans and our need to have things right away. Amazon was not the problem. When spending money on new tools, it takes time and diligent research to ensure the tools are correct for desired needs. Tick Tock, Tick Tock.

The first tool needed, a blaster. Needing more than a hobby sandblaster (this is not a model airplane kinda job) and not having the time nor money to build a heavy industrial blaster, a light-duty industrial blaster was used. Notice how I did not say “not needing” a heavy industrial grade blaster. Bigger may not always be better but not in the case of blasting. The bigger the better. Bigger blasters hold more sand, has a wider blasting range, and can remove more corrosion faster. Weighing these factors is a major determining factor. The trump card for our decision? Having a family friend in the blaster business who load us their unit.

Even once a new tool arrives, time is needed to read instruction manuals and to purchase or create additional tools needed to enhance original purchase. The blaster required two major modifications straight away. One: the installation of a water filter. Living in the coastal region means there is always water in the air. Oh sure, even on the hottest of days in the summer the air will dry out. But not much as compared to other locations in the dead heat of summer. Water in the airline means imminent death. Sand becomes wet and will clog in the hose or at the nozzle. Wet sand means inefficient blasting. Being as there was already a lot of blasting to be done, inefficient sanding means more time, more sand, more work.

Installation of a water filter bought at the local box store was easy to install. With the additional purchase of a ball valve and threaded nipple, the filter was also easy to attach. Water filters do exactly what their name says. They filter the water out of the airline. The trapped water is then extracted through an external nipple. Water filters come in various sizes and can be attached multiple in a row for more filtration. Even with a simple modification comes more time ticking away.

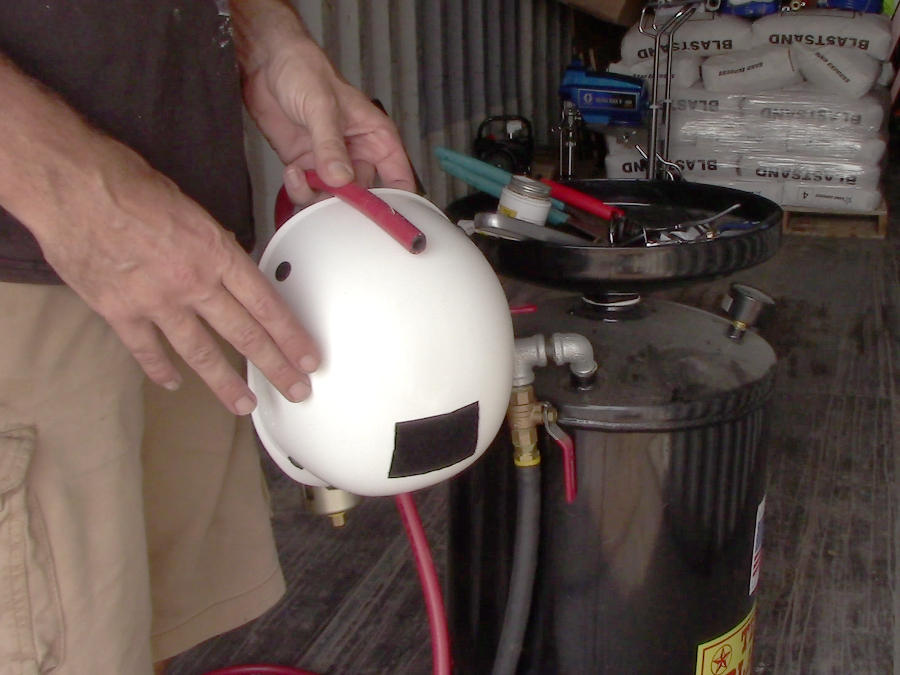

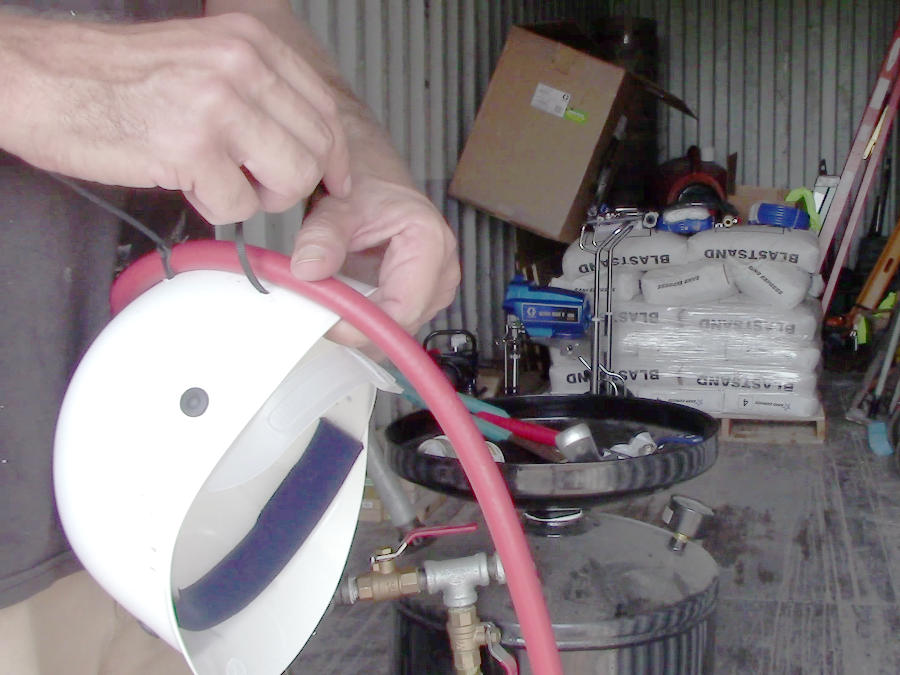

The second important was NOT a modification to the blaster itself but to the equipment used while blasting. A blaster unit comes with a very well, air vented, blasting hood reaching down to the shoulders. This is most excellent in design. Having a long hood means ease in movement while working without the worry of exposing the sensitive neck to the abrasive blast sand. After wearing the blast hood for a practice run and knowing an ample amount of time would be spent inside the hood, the Planner created an air hose system to move fresh air around hood while working. It was cheap, simple, effective, and only required the purchase of standard construction hard hat and an air hose. This modification was functional, not fashionable. Not designed to provide cool air, only to supply fresh air. Although cool fresh air would be a great modification! The air hose was attached to the hard hat with zip straps. The hard hat and hose attached to the blast helmet with super velcro for easy removal.

Once completed, the alternate end air hose was attached to the air compressor with a ball valve regulator. Now there are many safety concerns with this method of fresh air. For example, the use of an air compressor could allow small particles of oil to breathed in while working. But there are more important things to worry about than the longevity of healthy lungs. There was rust building up on the subframes by the minute. And that is how it goes with time. Blaster arrived one day. Blast hood modification took another two days. Tick Tock. Tick Tock.

Another tool needed to complete the blasting and painting was a painter. It was debated to roll on the paint. Yes, it would cost lots and lots less. But to what cost? Many, many, many years ago the Planner rebuilt the Airstream from the ground up. During the rebuild, a whole new frame was constructed, blasted, and painted with a high quality, specially designed paint. The cost for a gallon was more than the cost of the material to make the frame itself. The paint, however, has held up to 2.5 years of Texas salty air corrosion, traveling in North Carolina winters on salt laced highways, storage for two years, and now another 3 years of Texas salty air.

Seven years of wear and tear and the trailer has only been washed once. Once. Washing trailers is not high on my list of to do’s. Seven years and the only place where the paint has chipped and rust has appeared is on the retractable doorstep. Not the tongue that was modified and welded to twice. Not the frame underneath where salty air attacks and sits silently waiting to cause intense damage. Nope, just the broken step. Bearing all that in mind, the cost of tools needed, and the long-term maintenance of the subframes, an industrial spray painter was purchased.

Deciding to purchase was easy. Deciding what make, model and size was a different story. For now, the painter will be used to paint the subframes and the boxes both inside and out. Paint for this is very, very thick. Later when the boxes are done, the painter used will be much thinner paint. To meet both needs required paint nozzles in different sizes. But what sizes? That was the tricky part. A dart was thrown and several nozzles were ordered. The only way to determine how well they work, use them. As it turned out, neither nozzle was the correct size. Live and learn, right?

The final tool, an industrial grade air compressor. This was rented from the local tool rental store and was way more than was needed and it worked like a champ. A little loud, but hell, isn’t all machinery LOUD.

With all the tool and materials purchased all that was left to do was blast and paint. And wouldn’t you know it, the weather turned crappy. With rain in the forecast for Saturday, we blasted forward with our plans. No time like the present. Tick Tock and all that.

The setup went smoothly as did the blasting once the kinks were worked out. It was not fast but the work was not difficult. The most difficult process was ensuring the sand stayed dry, the blast tank remained close enough to the blast site as the blast hose was only 20′ and keeping the blast tank full. The tank could hold 1.5 bags of blast sand but then it was difficult to move in the uneven sand. What never reconciled itself was decibel level at which the entire operation ran. Holy-e-crap. It was so, so LOUD.

So LOUD. Why does everything have to be so loud? The air compressor was loud. The blaster unit itself is not loud. But to combine those two with the sand being expelled out and it was just too much for my ears. Wondering just how loud it really was, I downloaded a free decibel meter app. It worked fine and only told me what I already knew. LOUD, LOUD, LOUD.

After the first few bags of sand were used, the amount of sand collecting on the ground was enough to collect and reuse. Grabbing a used tarp revealed two things. One: roaches love burlap tarps. YUCK, YUCK, YUCK. I did try to kill as many as possible but I was outnumbered. I did warn them their days were over as I now owned little peepers who would be free roaming chickens quite quickly. Die you nasty little buggers, DIE!!! Two: the tarp was too small.

Scrounging around, this plastic tarp was found. Originally purchased to lay down on the weeds to choke out the briar and ever resilient poison oak, it was perfect for collecting sand. The above pictures show how much sand was collected after one bag was blasted. After two bags, the tarp was picked up and poured into a container.

Sand used for blasting is numbered by the level of sand blasting intensity. What went into the blast tank was blast sand #5. It is coarser than playground sand and a whole lot cleaner and drier. What comes out after being blasted is a very fine Zen quality sand. All that was missing in the bucket was the rocks and a little bonsai tree.

Before using this reclaimed sand, it was filtered with window screen to remove the large pieces of trash. Trash being dirt, sticks, rust, and weeds. It did not remove all the dirt but enough to run through the blaster.

Saturday morning did stay cloudy and looked as though rain was possible. Saturday afternoon was clear skies and slightly windy. Just another reason why weather forecasters are crap. One would have better results predicting the weather by using a weather rock.

Blasting and painting the subframes occurred in two batches. One on Saturday and one on Sunday. After the first section was blasted it was immediately painted. No reason to wait. Waiting means rust. Waiting means time. And time was running short.

With paint tools gathered, and the sun setting quickly, the painting job was commenced. Never having used the painter before required a whole initial prep process. More time. Tick Tock goes the sun. Look at long the shadows. Hurry hurry.

As it turns out, once the prep work was completed, the actual painting of the subframe took very little time. And what a job it did! The money spent on the painter was well worth it. The paint laid smoothly, held up to the light wind blowing, and was easy to use and clean up.

Time was not on our side as it turned out. It was well into dark, dark by time clean up was finished.

Sunday morning dawned cloudy and extra windy. Extra, extra windy. By Sunday afternoon, it was blowing so hard there was no sand to collect on the tarp. It just blew across the into the field. At least it wasn’t hot.

As with many things, things are much clearer in fresh light of a new day. Things like paint runs, exposed steel, and paint encrusted bugs. Character traits.

With an exception to the intensity of the wind, everything went the same on Sunday. Blast, blast, blast. Paint, paint, paint. The only modification made to the events on Sunday was the purchase of this painting jumpsuit. Painting is messy. Spray painting is even messier. Spray painting outside in the wind… Let’s just say it is a good thing there was extra paint.

All in all, this was a fairly easy job. Labor intensive and not something one should do without a helper. Modifications need to be made before the next blasting and painting job are already listed and numbered in priority. You didn’t think the modifications to the new tools was over because the tools have been used, have you? Ha, you must not know the Planner well. Nothing is ever perfect. There is always rooms for modifications. Just because something is set in concrete or welded into place does not mean changes cannot be made. It only means more work to fix, recreate, or modify. Simply put, it means more time. Tick Tock.

In case you are wondering why the video does not show painting of the subframes, it is because I accidentally deleted them from my phone before they had a chance to upload into the great wide universe. Oopsy Daisy.