Rain Water Collection System

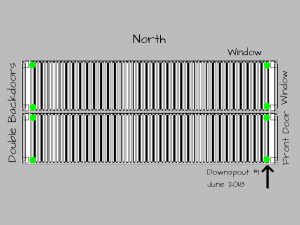

In the attempts at not naming this post as an Update to the original post, I discovered that somehow in all the work being done on the Work Box and the business housed within the box, the traveling for the Kid’s sailing, and the general life busyness, I never once mentioned the day the Rain Water Collection System took effect. The system has been mentioned several times in several posts since installation, but never the installation process itself. Such an important key, I would even say it is the most important key to the existence of Boxes in Fields, yet it was never posted. Amazing how that happened. Even more amazing is the fact that this is the only picture available of the original installation. THE ONLY ONE. Doubly amazing.

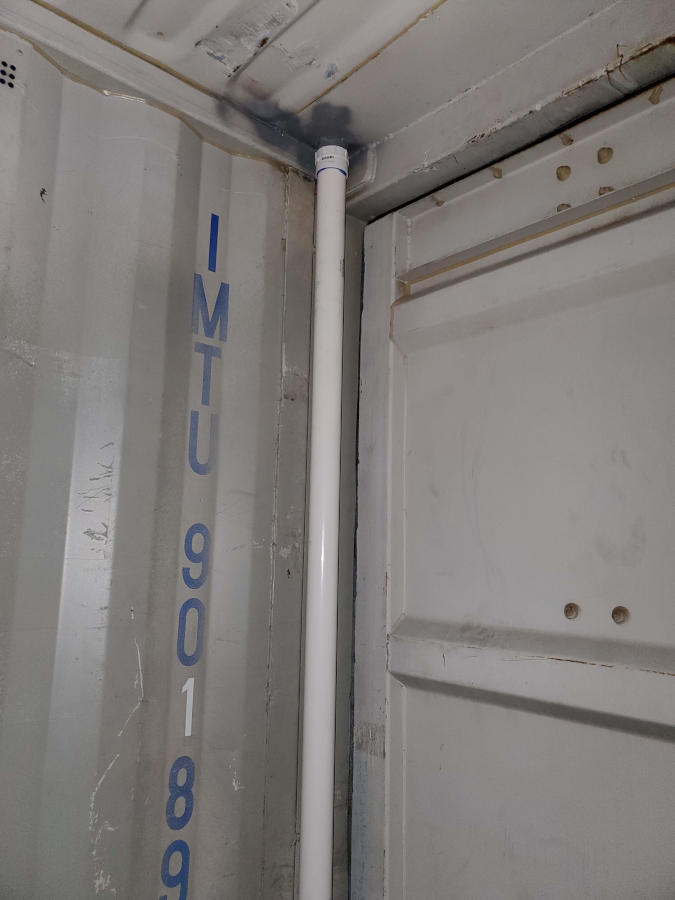

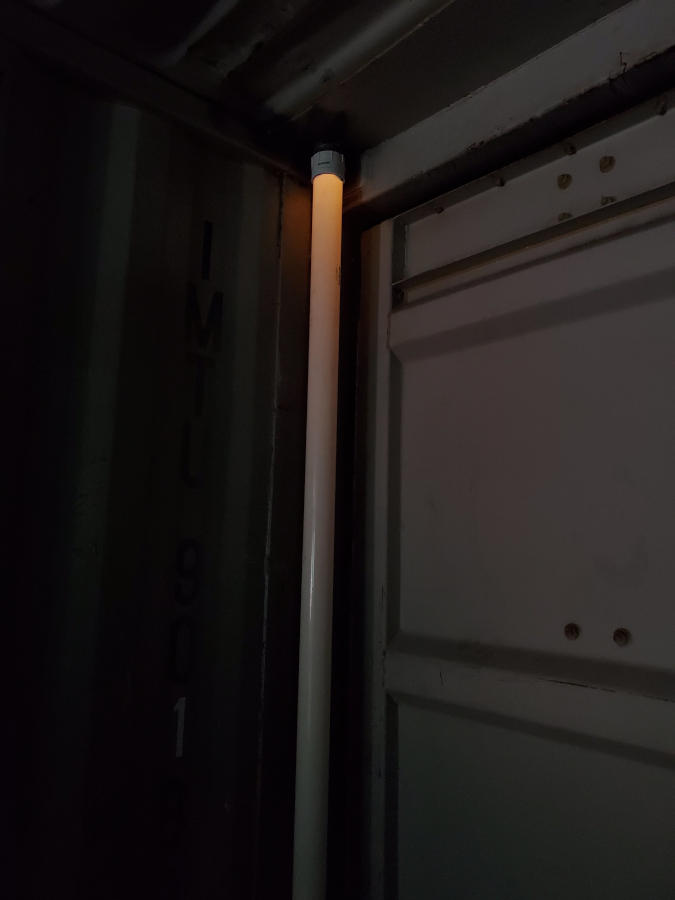

Not wanting to go into too much detail of the RWCS without pictures I will just give a quick summary. At the corner of each box, a 2″ hole was drilled into the ceiling and a metal inlet was welded into place with the top of the inlet being flush to the roof. Inside the box, seven of the eight pipes were caped closed and the eight downspout was attached to a 2″ PVC pipe that feed into the collection barrel under the box. From there, rain water was then transferred to the large 3000 gallon storage tanks. Not perfect or long term, just functional. That was June of last year.

Yes, June of last year. As in 16 months ago. Several thousand gallons of rain water have been collected via the RWCS through just this one down spout. Many times throughout the last 16 months, the 55 gallon barrel overflowed as the little pump could not keep up with the amount of water flowing though the singular 2″ PVC downspout pipe.

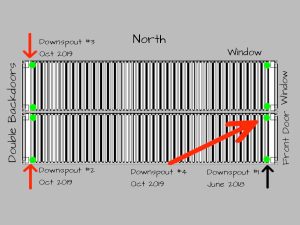

Since then Boxes in Fields has completely emptied one of the 3000 gallon storage tanks and the Planner is beginning to drive us crazy with his hyper awareness of water usage. Showers! You had a shower last night, right? Well then, tonight you can have a half gallon sponge bath! Needing more water, the Planner got to work on installing additional downspouts in the Work Box.

When the 2″ metal inlets were installed and capped with a PVC cap, the idea was intended for easy removal later. As it turns out, PVC will adhere itself to metal when rusty and become impossible to remove. No amount of handy dandy tricks would remove it. First it was the standard blue water pump pliers with cheater bar, then it was an oil filter wrench for more leverage, and after much cussing and tool throwing, out came the grinding disk.

Removal with the grinding disk was not any easier either. The hand held grinder did not fit easily against the ceiling. If held flat, it would not cut the cap in the direction in which it would split the cap, it would only shave it flush leaving the threaded portion still intact. To properly see what was being cut as it was critical NOT to cut into the metal down spout from the roof, the Planner had to wedge himself against the ceiling and cut at this awkward angle. It worked in the end, it was just slightly scary in the safety department. Grinder, cap, arms, and head all in a tight space. Ladder precariously close to open double back doors. One slip and its off with your head.

Once a small 2″ slit was made, the usage of a large screwdriver acted as a lever, and off it spun. Sort of. Having sand blasted and spot painted the roof a few weeks ago, between the rust and epoxy paint, it was evident as to why the PVC cap would not simply remove. It is good to know that the paint kept the metal insert from rusting into dust.

The next time RWCS metal inserts are installed in the Shop Box, something different will be done to eliminate this time consuming step. What should have been a quick hour or two project, once again turned into in all day affair. And that was just removing the caps. PVC pipes still needed to be installed. At least one cap came off as intended.

Next on the list of steps was to cut out two inch holes into the shipping container deck flooring. Cutting holes into the flooring is a not an easy tank as the flooring is made with some kind of layered weather protectant and is hard as nails. Does a great job at keeping cargo safe but boy does it drain a cordless battery in its efforts to cut though it. The cargo flooring is 3/4″ – 1″ thick depending upon container and is some of the most beautiful wood in its shavings. For all of the protectant materials inlaid into the grain structure, the wood never carries any chemical smell when drilling, never gives off an oily residue, nor does it ever burn or melt. Just look at those beautiful wood layers.

Before holes were drilled in the floor, an 8′ section of PVC pipe was held up to the roof and then leveled with the world to locate the hole on the floor. Lining up the PVC with the world was not the only consideration to take into consideration. The tubing must be accessible to repair and yet out of the way for work related reasons. They have to align with the flooring substructure underneath and not cramp corner of the Conex box pockets. As you can see, even with a test hole drilled, the alignment is not always ideal. Luckily, this time, the PVC makes a bend directly below the hole and this corner pocket is avoided.

Installing the PVC piping on the back outside corners of the box was easy as it was exactly like the front outside corners, it was simply a straight pipe down into the floor. A union to the metal down spout and PVC all the way out the floor to the underside of the box and there were done.

The inside front PVC tubing to the floor required more forethought and planning. Wanting to ensure there was little water flow restriction due to the bends in the tubing, the Planner doubled the size of the needed PVC diameter as compensation. With four of the eight two inch PVC down spouts now installed, water loss over the side of the box edges should be kept to a minimum. Water overflow out of the barrel is always a possibility, it is nature of course and deluges due occur. These downspouts were designed for the average rainfall over the average an amount of time.

What should have taken a less than a day to complete took two but the results were worthy. Boxes in Fields is another step closer to a completed Rain Water Collection System in the Work Box. There is of course, the remaining two inner downspouts at the back of the box, the remaining two downspouts around the window on the front wall, the Shop Boxes, the House Boxes, and the Kid/Guest Box to complete. But hey, one step is one step. Did I mention that these new down spouts only drain out in the world and are not as of yet collected to the temporary 55 gallon bucket. Oopsies…