Fabricated Beam, Part 1

Think back, way back, to another time but in the same place. A time before flooding, hurricanes, freezes, and dumpster fires. A time when Boxes in Fields was more of an idea than an actual living and breathing place of peace and tranquility.

Peace and tranquility. Ha! That’s funny. There is nothing peaceful or tranquil at Boxes in Fields. Ok, that is not true. If you eliminate all things human, then the birds and bees, wildflowers and trees, sunrises and sunsets are the epitome of peace and tranquility.

As you are reading this it only proves Boxes in Fields does not exist in a vacuum chamber of peace and tranquility. Instead it is composed of humans, chickens, and a cat; hammers, grinders, and machinery; bickering, music, and the general hum of living. We try to keep the yelling at a minimum, run the machinery, tools, and equipment between sensible working hours, and be respectful of the quietness at all possible moments. However, there are times when the neighbor is cutting his yard at midnight, hammering on the new room expansion at predusk, and doing human things that just inevitably make noise. Humans are inherently noisy.

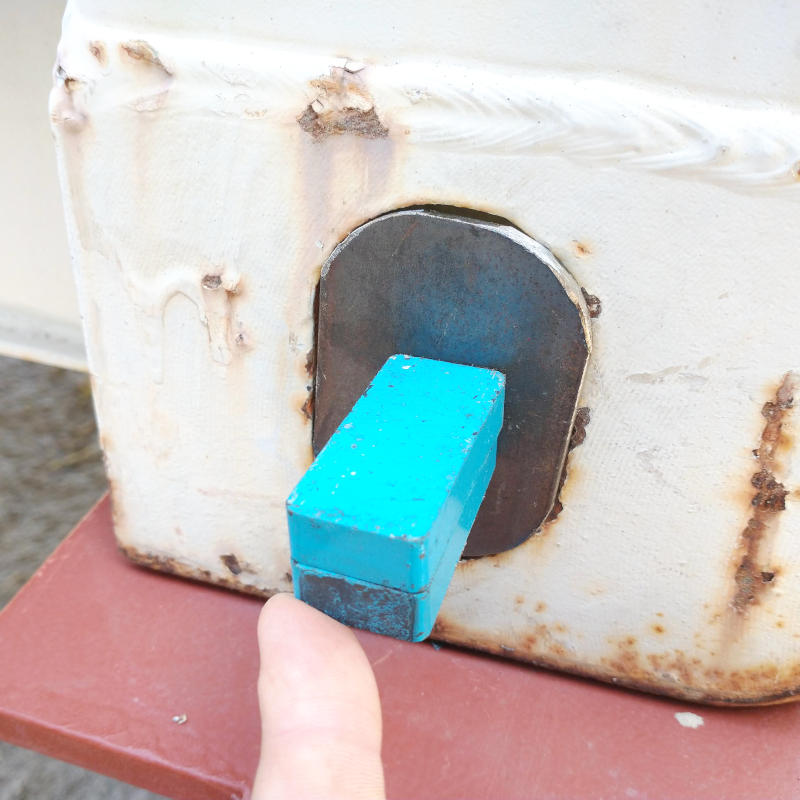

Trying to adhere to this mutual respect of quiet, Boxes in Fields tried not to start the equipment, machinery, and hand tools before 8am. But just as you are adding to your home, we too are adding to ours. It just happens our requires more loud tools and equipment. Sorry, we really do try. So with a silent plea of forgiveness, Boxes in Fields started their last Monday of the month at 7 with a grinder and a box edge in need of cleaning.

As I was saying. Think back to a time long before, when this journey was fresh, the blog was new, and the energy levels were high. Back to a time when the Planner had grand ideas, mostly which were implemented. Back to a time when the Kid wanted to be helpful, mostly without complaint. Back to a time when our family and friends thought we were normal, well mostly normal. Back to when the Planner designed and implemented a beam to support his open floor plan in the Shop Box using an almost 40′ W14x22 wide flange. It has eliminated any deflection in the ceiling and if we had another section just lying around, the Planner would have used it. But we don’t, so we didn’t. Instead he designed the Dwelling Box beam using 1/4″ flat bar. Two pieces of 1/4′ x 10′ x 20′ and one 1/4′ x 6′ x 20′.

Using the three pieces of flat bar, the Planner will fabricated his own beam to support the middle of the Dwelling Box. One that would decrease the floor flex, one that would be lifted into place without the use of heavy equipment, and one that would not be obtrusive and detract from the openness under the box. Lifting into place required the Planner at one end, myself at the other end, and the Kid to run between both sides attaching F-clamps. Once the clamps were in place, the middle end of the flat bar was pushed up tight against the edges of the box and welded into place. To secure the beam middle, a bottle jacked pushed the beam upwards and a c-clamp secured to the box channel. Then a pull post was welded on to the outside edge of the beam. Threading through a stopper on the box allowed the metal to be pulled tightly removing the natural bending. In my opinion, this threaded pulling device was a pure stroke of genius on the Planner’s part. Pure. D. Genius. Tomorrow, tacking and welding.

After clamping and pulling and pushing up several times over, the Planner was finally happy with the position of the flat bar. Now to tack. The final welds will be two inches in length, eight inches apart, both inside and outside the flat bar. But for now, the tacks are just enough to hold the flat bar into place. Tack, tack, tack. Move, readjust the C-clamps, the welding leads, the sitting block (outside), the half sheet of plywood (inside), the shade. Repeat.

With the sun finally on the west side of the box and the tacking complete, the Planner got down to the business of welding. Starting at the outside was the easy choice as the Planner just sat in a chair with welding jacket over his legs for protection. Weld, weld, weld. Move the chair, the leads, get two new welding sticks, hydrate. Repeat. Repeat. Repeat. Switching to the underside of the box took a few iterations of trying to get comfortable. Using the Gorilla cart didn’t work as the angle was wrong to see correctly. Remember how I glad I was that the Dwelling frames were a foot or so shorter than all the other framework? Well, guess what? The Planner does not fit sitting up. Add a welding hood and the Planner had to bend over resting on a timber to prop all the while his head was wedged between the floor joists. Poor Planner. West box flat bar installed. Tomorrow the east.

Wednesday morning started out with hope for a break from the intense summer heat. The skies above were cloudy, the clouds looked dark gray and ominous, and the forecast had a small percent chance of rain. Sadly, by early afternoon the clouds had broken, the humidity had increased, and ground remained dusty. At this point in the game it is going to take more than a small percent of rain to saturate the ground. We are talking days of slow and steady rain dumping three to four inches at a time. Luckily, the time between the clouds and the sun allowed the Planner to be very productive.

Being productive with welding, I attempted to be productive by removing and cleaning clamps and attempting to keep the boxes from catching fire. Attempting. Giving up on the clamps, I just watched for fire and tried to keep the Planner from catching on fire as the sun was intense. East box flat bar installed. The bottom portion of the fabricated beam cannot be installed until the boxes are moved together.

Thursday and Friday were spent removing all but two small portions of the inner wall of the west and east boxes. This is relatively simple work, just slow in procedure. Plasma cut along the top and bottom edge. Using hand grinder with cutting disc, remove the wall anchors and remaining bottom edges.

Once cut along top and bottom, use plasma cutter to, remove portions of wall into moveable sections. Drag out portions using chains and stack for later collection with forklike. Remove additional sections until done.

Finally Friday and the workload has not decreased, nor has the heat and dry weather. In fact, if anything, the workload has gotten harder and it most certainly is hotter as there are no clouds in the sky. And when you see the Planner by 930am already this hot and red in the face, you know it is going to be a long, long day. Today was a very trying day. The work today, no matter the weather, is always difficult. Standing in one position for hours on end grinding. And grinding. And grinding. First, with the 7″ grinder on the disc edge, remove the wall material left from the plasma cutter. Second, with the 7″ grinder on the flat surface, smooth the face plate.

Fourth, using 4.5″ grinder with flapper disc to achieve desired smoothness. Hours and hours later, the metal edge of both boxes are ready for the flat bar that adjoins the two together. This is the same procedure that has been done in both other boxes and has worked wonderfully.

The flab bar is tacked into place now on one box and then once the boxes are pushed together, the second box is tacked. After being able to stay in the shade of the boxes, the Planner is now in the full hot summer late day sun. Poor Planner.

Closing out Friday, the Planner decided at the last minute to seal off the corner pockets. He said since he was already hot and sticky, red and crispy, that he would finish out the pockets. With the sun at its hottest point in the west sky, the Planner sealed off the boxes as the Kid and I watched from the shade of the closest tree. Poor Planner.