New Tools

I have put this off and put this off and have even omitted discussing in several posts because I had this great idea to write a tool post. Yet here it is, a year later and I have decided now is the time and I have more tools than anticipated. In order to proceed, clarification is in order. Some of these tools are new to us on loan and some of these tools are new to us because they were purchased. I did not include borrowed tools that were used before such as table saws. For example the table saw was used years ago when building the Airstream. No, these tools even if old when borrowed are new tools to use because they had never been used by us before. Does that make sense?

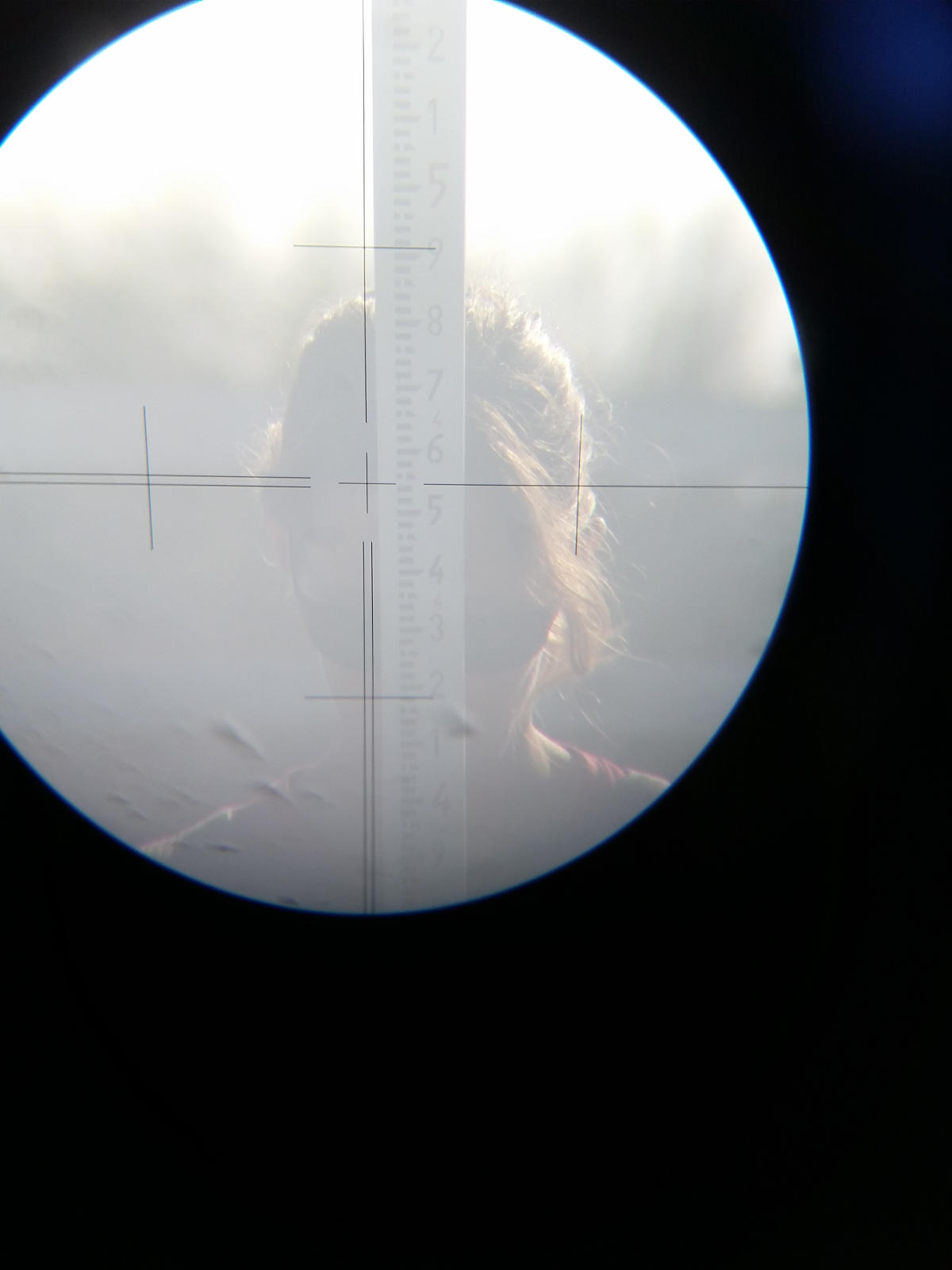

One of the first new borrowed was this well used transit. Man oh man. This tool came with a very detailed instruction packet for usage. Not only was the packet used, Google was sourced, and phone calls were made. Upon the initial setup of this tool, it came in very handy. The transit was used to determine where the shop was going to go and then was used to set the footings. The shop would not be level if it weren’t for this tool. It beeped, it buzzed, it went whirrly whirrly. Thanks Grandma for the loaning of this fancy tool.

The next tool was our very first large purchase towards Boxes in Fields, other than the property itself. This 38′ gooseneck was purchased in Big City #2 for the sole purpose of hauling conex boxes. To have a conex box shipped to our location added anywhere from $500-$2000 in cost. If everything goes as planned, hahaha I’m laughing here,eight conex boxes will be needed. Simple math here: 8x$500 is more than the cost of this trailer including wear and tear on the truck. When the trailer is no longer needed, it will be sold. Recouping some of the cost.

The first small hand tool purchased was this chipping hammer. Don’t know why this Estwing chipping hammer was bought when there was not a current need for removal of welding flux. However, in the case of Jack, Jason or Freddy showing up, the hammer can be used for self defense.

In the unloading of the very first conex box used for storage, tools were created to help assist in the removal process. They worked great and were made from scrap materials. As the box moved down the trailer, the back guide kept the box straight and the rectangular side guides were moved down to keep the box from sliding off the trailer. Simple, yet effective. The back guides were used for the second box but not the third and fourth. The side guides were used for all boxes. Think we got our money’s worth.

The Planner had an impulse purchase with the chipping hammer. I had an impulse purchase with this magnetic tape measure. What was supposed to be my tape measure has now been reappropriated. Thief. Purchased back in November, the tape measure works well. In fact, it works too well meaning both a magnetic and non-magnetic tape measure must be carried at all times. There are times when the magnetic tape is not needed causing more drama than needed.

Can you believe this is only the second grinder to have even been purchased by the Planner? The first one was purchased way back in college and was a used 4″ DeWalt from a local pawn shop. According to the Kid, this new purchase is a “man’s grinder”. Whatever that means. Somewhere between the old 4″ and this new 7″ Bosch grinder, grinders have taken on a genders role. Have used the DeWalt grinder many, many times and never once was concerned about it not being a “man’s grinder.” Only men gentrify their tools.

Already posted about this once before way back when I mostly wanted to include the purchase of these new gloves. These new gloves suck! How can the same company produce the same glove within the same year and be two totally different products? These crappy gloves were purchased in back in November and they have been worn less than a dozen times. One day in the next near future, the favorite gloves on the right will be no more and it will be a sad, sad day.

This here Lennox PVC tubing cutter purchased in December during Friends in Fresh Water Places days. The Planner wanted the house brand and I wanted the Lennox brand. Brand names are not top priority at Boxes in Fields. Research, word of mouth, and general usage determines what is bought. The first selling point of this tool was the ratching feature. The Planner could cut, I could cut, and the Kid could cut. The second selling point was replaceable blades. The third and final selling point was it’s capability to cut 1-5/8″ OD. As a review, yes it does cut 1-5/8″ but it is a work out. Also, if using cheap PVC, it will crimp the PVC as it cuts. This tubing cutter is designed for pressurized PVC and workers with large hands. On a side note, yes what you see in the picture is what really happened. A trip was made to the local hardware store for plumbing needs and the beep-beep was taken. PVC tube comes in 10″ sections and the car can only handle 7″. Never underestimate the power of the beep-beep! Oh, and don’t mind the Kid, he is normal, I swear.

Uh. Just said in the last paragraph Boxes in Fields does not buy name brand for name brand. However, if a name brand holds true to its name and quality, then they are continually purchased. The Planner has a soft spot for Estwing. As it turns out, Estwing tools have held true to their integrity. And trust me when I say, when a tool fails, the Planner is done with that tool brand. I have seen brand new tools chucked into the trash bin. Hey, if the shoe hurts why wear it?

In the building of the frame for the footing placement a new square was purchased. There is somewhere in storage a square that has been handed down from generation to generation. It is in storage and an square was needed immediately. The Planner and the Kid purchased the square on the left and hours later called me to purchase the square on the right. Just because you have a square does not mean form boards will be square. Experience is needed just as much a correct tooling.

Footing work required many new tools as it turned out. Didn’t even realize it until writing this post. Yes, most tools are multi use but they were first needed for footings. Another homemade tool was the concrete shoot. A couple of pieces of 2×4’s and a sheet of tin and te-de a concrete shoot. Worked like a champ too. It was easily moved and easily cleaned up.

Yet, another tool was the 4.5 gallon shop vac. Holes dug were deeper than the water table allowing water to slowing seep up. In order for concrete to set correctly, excess water had to be removed. This here, the first hole, was the worst out of all ten holes. Something like 8 buckets of water were removed before pouring concrete and another one or two was collected during pouring.

The last tool created for the footings was this here re-bar concrete packer. As concrete is poured into the holes, air pockets are created weakening the structure. The rebar is used to remove air pockets while packing the concrete tighter. Fancy packers are electronic and vibrate the air pockets up and out. Those are expensive and this worked just fine. In fact, once cardboard tubes were removed after curing process, concrete showed visible signs where the packer (that would be) slacked on the job. Packing concrete is aggressive work, just look how smooth the re-bar was after ten footings worth of packing.

Ensuring the cage is straight within the hole is uber important. Having a magnetic level helped. The real reason the magnetical level was purchased is once again because all boxes are metal. Makes things easy. Concrete footing usage was an added bonus.

Tools for tools. Some would not classify this sorting box as a tool. Is not the basic understanding of a tool is simply something used to accomplish a task? Therefore sorting boxes equals tools. Sorting boxes were purchased to house various supplies. This box is specifically for screws. There is one for nuts and bolts and one for nails, and one for who knows what. The boxes stack nicely together and are easy to access and modify.

Ah, the final tool purchased during the footing process. New lineman pliers for the replacement of the original pair purchased too many moons ago to remember. Why? Needed to bend wire around rebar to create concrete cages, of course. Now the Planner has a pair and I have a pair. And yes, I immediately stole the old pair for my usage. Why in sams hell would I not want the new pair? They are stiff and hard to manage. Smart woman if I do say so myself.

Oh, I remember the purchase of the step bit as if it was yesterday. Purchased for the making of the little peepers home, this simple tool was hard to find. Everybody had them but none were in stock. If one was in stock, it was the wrong size. Really designed to make old holes bigger in a step by step fashion in metal, this tool worked well to make new even sized holes in the peepers home too.

Curiosity killed the cat. Wondering how hot the trailer was getting now that spring had arrived, this heat temperature gun was bought just for funzy. Should never have bought it. The actual reading was worse than the perceived heat. It really is hot inside the tin can.

Ensuring square seems to be a running theme here at Boxes in Fields. There has been a transit, a magnetic level, two squares and now there is a line level. This little tool is used to make sure the chicken coop’s top board was level. I said straight but was informed the correct terminology is level.

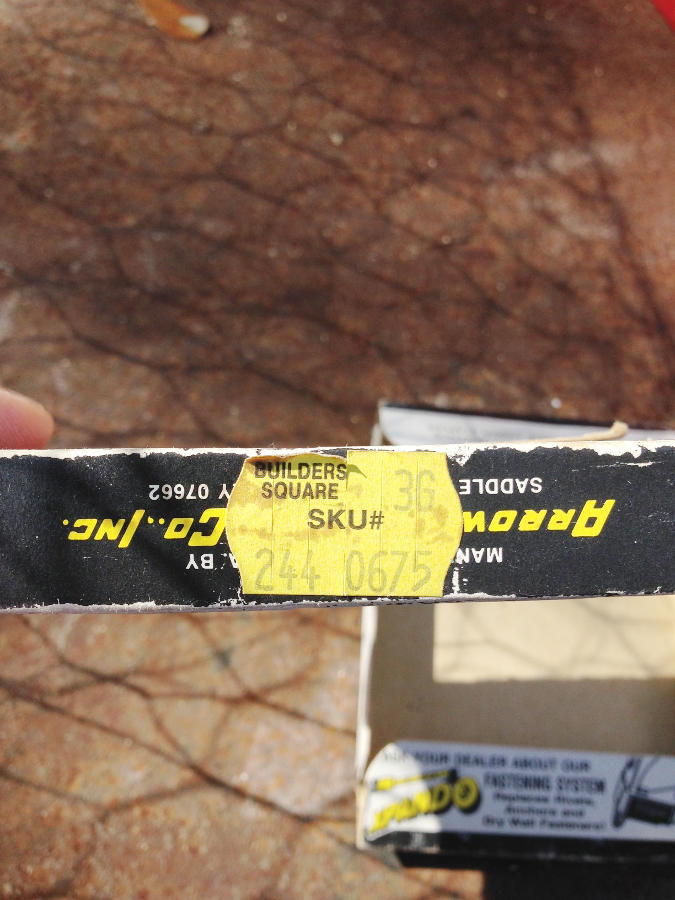

In the closing in of the chicken coop with wire mesh, the Planner dug out Daddy’s old trusty staple gun and staples. What a flashback. The stapler and staples were in this Jansport messenger bag from way back in the 90’s. The stapler was modern at the time of inheritance (only fifteen years old or so. I know this because I bought it for daddy with my own job money for his birthday.) The staples are older than mankind can remember. Can you read the price sticker? Ha, price stickers. Remember those? The price sticker says Builders Square. Builders Square was the local hardware box hardware store before the much larger nationwide box hardware store purchased them out. While this tool may have been state of the art back in the day, the use of this borrowed pneumatic stapler is state of art today and maybe even tomorrow. Once again, had to read the extensive instructions, but once used, I would not trade its loudness for the old fashion stapler. Thanks Doubter for the loaning of this tool.

This was probably the only tool, so far purchased, that was purchased for a single use. Next to the pneumatic stapler, this made completing the chicken’s coop bearable. Working with chicken wire is for the birds by the way. It twists and snags and is not easy to install snuggly.

Working on the chicken coop required the use of several power tools. To help eliminate time wasted on switching cords, this splitter was purchased. It will be of great use in the Shop Box, too. Sometimes the cheapest, simplest tools are the best.

As previously stated, this sand blaster was not purchased but loaned to us from the business owner. The trade off was free usage for critical assessment of the product. The blaster was used and criticized and will be used again for the house. Upon its return to the business owner, it will be far from slightly. It will be well used. Thank you Texas Blaster.

This painter, on the other hand, does belong to Boxes in Fields. The tricky part in learning the ins and outs of the painter is the nozzle to paint correlation. Too big, too small, too wide, too narrow all have an effect on the painting results. Not to mention the 20 mph winds blowing.

Ahh, my beloved ear protectors. I wear these over the head, full ear protectors all the time. Many times have been noted I am still wearing them and nothing loud is running. As the heat gets higher, I have experienced sweaty ears. Gross, yes. Protected ears, yes yes. Fashion statements are not my forte.

Do you have any idea how many times I have heard “one day when I get my plasma cutter”? Me neither. After the fifteen hundred thousandth time, I stopped listening. Well, that time finally came. Never have seen a happier man. The box was unveiled and there it say for the next week on the shop floor. That’s how it is. Get a new shiny toy and it is played with for less than a day. Many weeks later when the Shop Box door was being cut, the plasma cutter was final put to its first test. I have been told it was worth the wait.

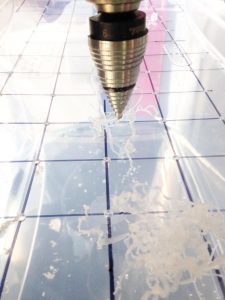

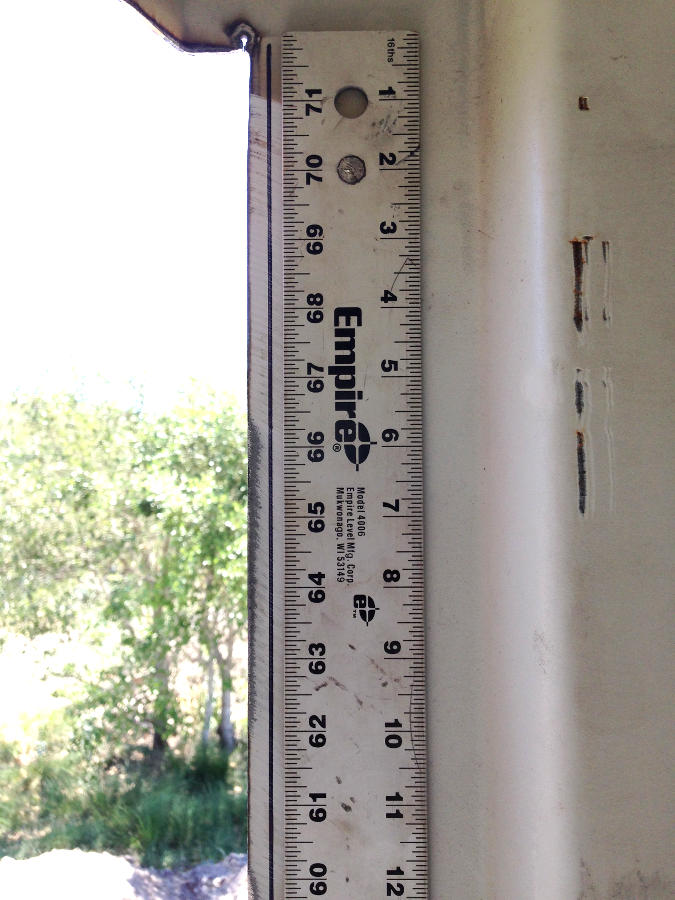

Magnets are Boxes in Fields’s new best tools. They are used everywhere. They attach the water filter to the wall so it is out of the way while still running. They attach the 8′ ruler to the wall to be used as a guide for the plasma cutter. They attach the door hatch to the frame for mounting assistance.

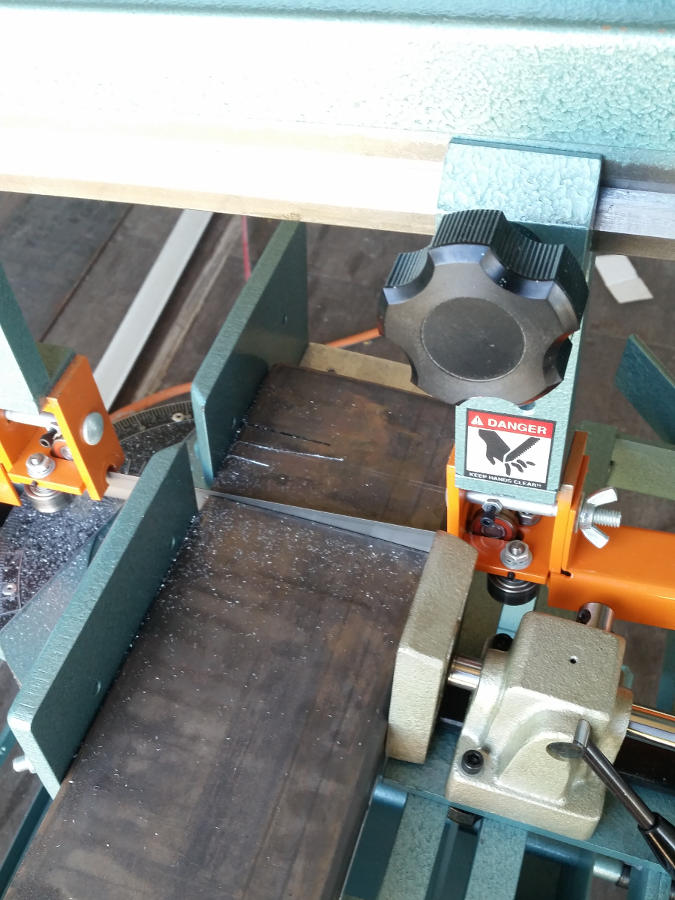

Last but most definitely not least was the new band saw. An old band saw had been given to us but it was not large enough to cut the materials used at Boxes in Fields. This toy came in while the Kid was in space and the Planner took days and days to play and learn this new tool. Have to say, I am quite impressed with 1) how quiet it is compared to the old model and 2) how professional the cuts look.

All in all, most of the tools purchased are under $20 so buying a new tool here and new tool there does not break the bank. Tools like the band saw and the painter come out of the Boxes in Fields savings account and it is dwindling quickly. Purchases of this size are debated and debated against the cost associated and the cost of doing with with less than adequate tools. In order to do a job correctly sometimes the purchase of a new tool is required. If purchases are done smartly, tools can always be sold to recoup some of the money. Tools are required for a job, therefore, tools are required for purchase. Many tools have been purchased thus far and many more will be purchased before it is over.