Shop Box Boxes

As part of the Planners sudden need to be more organized in both life, work, and Boxes in Fields, the Planner came to the realization he needed more shelving and boxes for his Work Box. Currently his shelf and floor is laden with 5 gallon buckets, cardboard boxes of various sizes, dimensions, and weights, milk crates, and one wooden 4x4x4 crate. All are filled with random assortment of tools, supplies, left over materials, and other various assemblage. Over time, contents will move from one bucket to another. Tools will make their way to a final home as they are used or needed. Mostly the buckets are filled as they are used in whatever project and then left with remnants. There are no less than three buckets and two boxes filled with electrical/plumbing parts. This does not include the shelving/buckets of electrical and plumbing located in the Storage Boxes. Work Box storage boxes really are needed.

Boxes had to fit the shelving units built two summers ago and they had to be sturdy enough to be lifted above the head over and over again. I would like to say these boxes are going to be rarely accessed, but that would be lie. Not accessed daily, they are accessed weekly and that is enough to need to have them organized.

During our holiday visit with family while the Kid and I built fires and collected river rocks, the Planner, the Doubter, and the Uncle made boxes. Usage of the Doubter’s wood tools made quick work the boxes.

Two sets of nine boxes. 18 boxes total. All joined and glued and stapled. No corners were cut as strength and durability are important.

Only upon completion of the boxes did the Planner and Doubter realize the boxes really should have had lids made. Oh well, they are just storage boxes anyways.

Several weeks have come and gone since completing the boxes. In the span of time, the Planner (words muttered under his breath) again had to dig inside the wooden crate for tools to help the Kid made his chicken steps work and then just last week we both had to work around the 20 odd buckets and boxes on the floor while working on an actual work project. It was decided now was the time to finish the shelf project. No time like the present.

Having three full days of warm summer weather ahead was the perfect time to do it, too. Material was dug out off the shelving unit and thoroughly cleaned. Almost two years of grinding, plasma cutting, welding, and environmental hazards build up heavily upon open faces.

We are not talking a slight dusting here, we are talking about an 1/8″ layer of grime. It is thick and sticky, oily with residue, and slightly rusty. Messy. Cleaning this 2×2 tubing is yet another reason why the boxes really did need lids. Now more than ever, the Planner has to design a box lid that fits snugly and can be built without the usage of wood tools.

Once cleaned, the materials were cut to length and corners rounded. Like the Kid with his step stool, rounded corners are not needed but they look more classy and are safer during prep work.

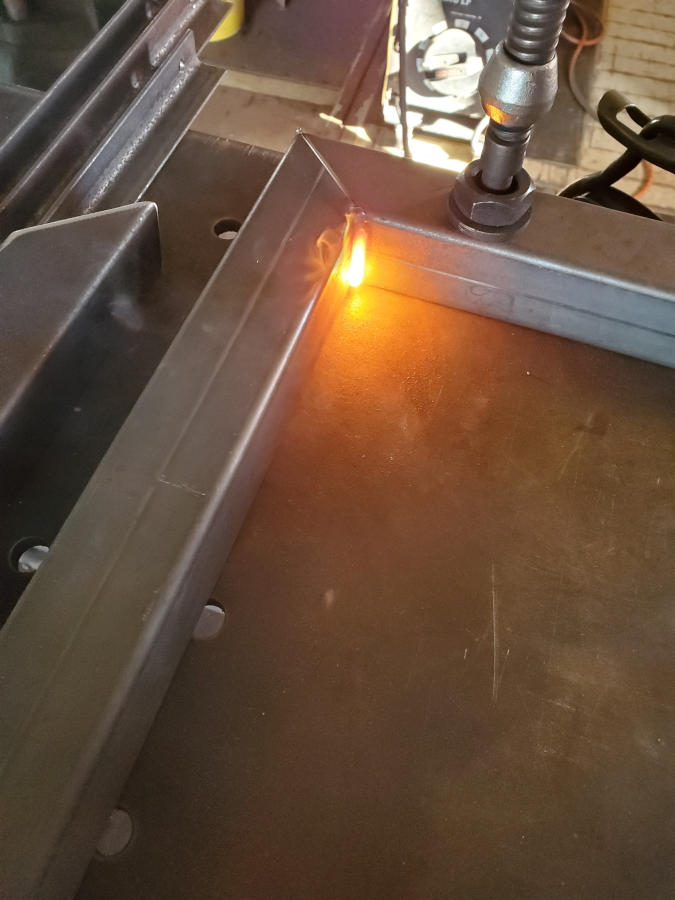

Measure and anchored to the work table, the shelf was checked for square again and again. Meeting proper length, it was tacked, fully welded, and then ground smooth.

During framework cool down, the existing shelving was prepared for welding with the paint stripped at the correct mounting points.

It was then welded into place,

primed,

and painted. New wooden insides were fitted and screwed into place and ta-da, completion.

Really only took a solids weeks worth of time, the new shelf and 18 boxes look professionally organized. Now to fill with crap. Wait, I did not mean crap. I meant important crap.