Shop Box Water Collection Part 1

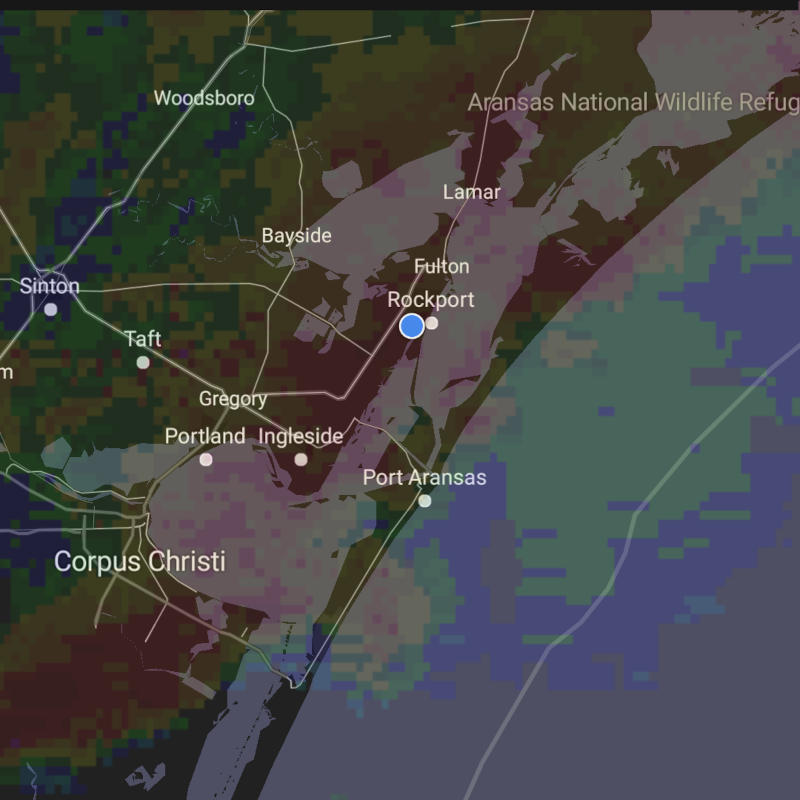

If 2020 was the year of the Dumpster Fire, 2021 at Boxes in Fields will be the year of Climate Change. I’m sure it is just the first of many years for climate change, but climate change it will be. Boxes in Fields started off with rain, then tried to freeze in February, then tried to float away in May and June and July. If climate change is bringing this much rain one year and then no rain the next year, then Boxes in Fields needs to start collecting more water when the water comes.

At the end of September 2020, the Work Box water collection system was finally fully completed in Blinded by the Light. Almost a year to date, the Planner started on the Shop Box Water Collection. But first before the downspouts could be installed, first the roof had to be repaired. The second box has always had a potential for ponding water as the roof was caved inwards from external damage. This area was hit with the needle scaler exposing all weak links in the roof. Thinking it was going to be one or two spots, the Planner was kinda taken back by how many pin holes there were to fix. Tiny holes in the ceiling left for some really great images on the floor. Throw is some dust swirls and the whole scene was like a fairy tale, except with holes in the ceiling.

Two weeks later after some more rain, the first of the only four downspouts were drilled into the Northeast and Southeast corners of the Shop Box. Unlike previous drilled holes, the Planner hauled the heavy a**ed mag drill up the ladder. Every step of the ladder I held my breath to the structure, strength, and integrity of the ladder carrying a 200lb man and an 80lb drill. The ladder says it was weighted for that and then some but each step gave as the Planner climbed his way up.

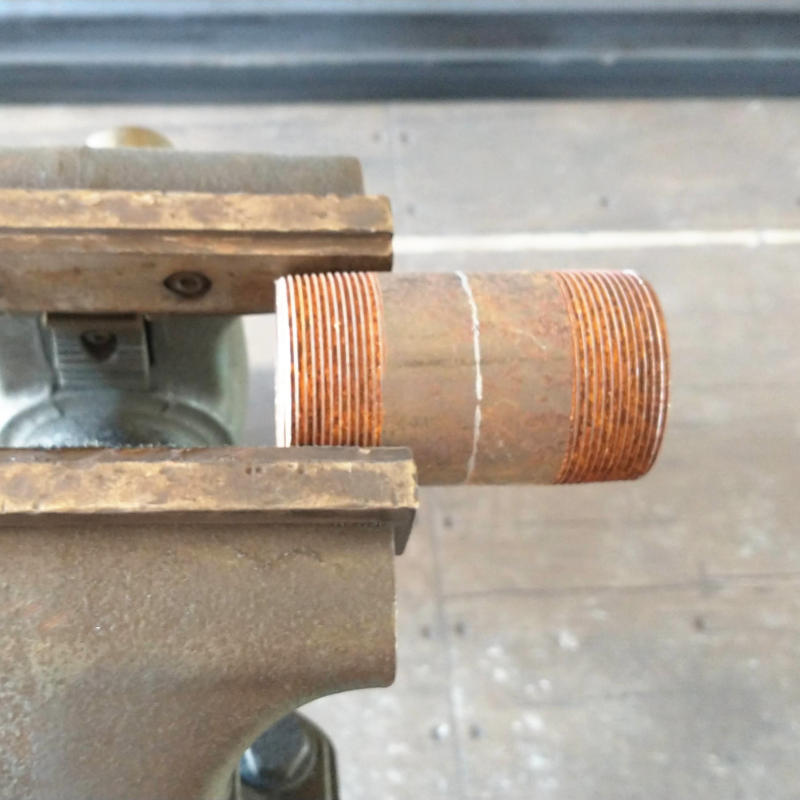

Heaving that solid block of steel up the ladder might have been an excessive amount of work, but the actual drilling job was a snap. It took more time to correctly situate the mag drill than it did to drill the holes themselves. With holes drilled, four metal downspouts from 2″ close nipples cut in half were welded into place and secured against any upcoming rains with 2″ PVC caps.

Needing to be able to have easy access to all sides of the double back doors and not being able to combine downspouts in the middle like in the Work Box, the Planner created a whole new water collection downspout system at the back doors. He created a water 4″ water trough running from one side to the other with a 2″ downspout at the southwest corner.

To allow for continuous run through the middle of the boxes, both the boxes and the beam above had to be cut to allow for the trough. The tough started out as one solid 4″ square tube with a 2″ hole drilled out of one end with a 2″ downspout welded into place. Then the top of the tube had it side removed creating a U shaped trough. As expected the tube warped and bent all out of shape making the once almost rectangle cut into the ceiling a very tight fit in some spots and too big in others.

Luckily the Planner saved pieces to weld into too big of holes and had a grinder to remove too tight of fits.

The tough was tacked into place and then welded fully moving back and forth from the North wall to the South wall to help offset any excessive heat buildup.

From inside the box, the tube trough was welded around the individual boxes and along the beam. This turned out the be the hardest of all steps in any of the downspouts installed. Even harder than when removing the rusted PVC caps from the metal downspouts in the Work Boxes. Finally after much frustration and looking like mud dauber nests, the trough was fully welded into place.

A cap was installed on the 2″ downspout and the trough was tested for leaks. Several five gallons of water were poured into the trough and only one leak was discovered. At the beam box joinery, of course. Tested again, the trough held up dry and not a moment too soon as more rain was on the way. Again.

A week later after all the rain was done and gone, five floor holes were drilled out and the four east side PVC pipes and one west side PVC pipe were installed. Now the undersides need to be connected to each other and then plumbed into the PVC lines that run underneath the concrete pad. Not bad for a few weeks for worth of work around rain showers, paying job duties, and a few home chores to be discussed in the next post. If another trough was to be installed again, a few modifications will be applied but it will be first choice over four downspouts and PVC pipes into the floor.